PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

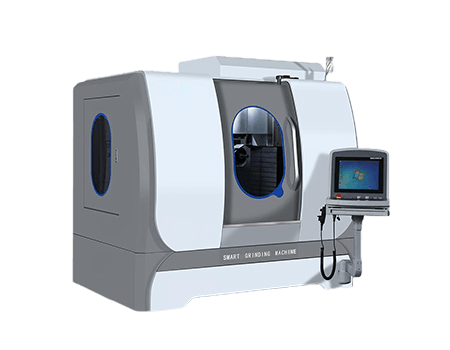

5 Axis CNC Tool Grinding Machine QD580 Series

QD580 is a high performance 5 axis CNC tool grinding machine with high rigidity structure and new generation control system, designed for precision machining and resharpening of various complex shapes of milling, drilling and forming tools, which are widely used in aerospace and automotive manufacturing. This 5 axis CNC tool grinder combines advanced technical parameters and a user-friendly operator interface, making it possible to improve productivity while ensuring machining accuracy and stability, making it particularly suitable for high-end manufacturing needs.

- Max. workpiece diameter: 32mm

- Max. workpiece length: 260mm

- Max. workpiece groove depth: 20mm

- Max. workpiece weight: 20kg

Specification | Unit | QD580 |

CNC System |

| SYNTEC210MA-5E |

Max. workpiece diameter | mm | 32 |

Max. workpiece length | mm | 260 |

Max. workpiece groove depth | mm | 20 |

Max. workpiece weight | Kg | 20 |

Max. power of grinding head (direct drive spindle) | KW | 24 |

Grinding wheel size (CBN/diamond) | mm | Φ50~Φ200 |

Spindle speed of grinding head (frequency conversion) | rpm | 1000-6000 |

Vertical travel of grinding head (Z axis) | mm | 350(-100~250) |

Table travel X axis/Y axis/Z axis |

| X:520 / Y:540 / Z:350 |

Rapid traverse speed of linear axis | m/min | 15 |

Workpiece spindle speed (A axis) | rpm | 200 |

A axis rotation range |

| ∞ |

A axis spindle bore taper |

| ISO50 |

Pneumatic clamping range | mm | 3~20 |

Workpiece clamping range with SCHUNK chuck | mm | 3~32 |

Max. rotational speed of grinding head oscillation (C axis) | rpm | 75 |

C axis rotation range |

| 320°(-225°~95°) |

Workpiece spindle center height | mm | 135 |

Radial runout of workpiece spindle | mm | ≤0.005 |

Radial runout of the grinding head spindle | mm | ≤0.005 |

Cylinder clamping force adjustment range | Kg | 800-1000 |

Linear axis resolution | mm | 0.001 |

Rotary axis resolution | ° | 0.001° |

Cooling workpiece flow rate | L/min | 60~80 |

Cooling workpiece oil pressure | MP | 0.5~0.6 |

Power supply |

| AC 380V 50HZ three-phase |

Total machine power | KW | 30 |

Machine size | mm | 2200×1600×2400 |

Machine weight | T | 5 |

Features

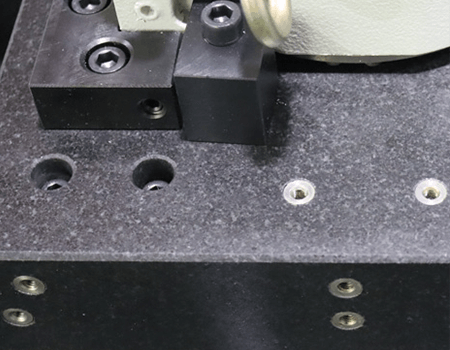

- The 5-axis CNC grinding machine has an atmospheric appearance, friendly man-machine interface, and adopts natural marble components for good stability of the machine.

- The machine tool adopts the new generation 5-axis linkage control system and Yaskawa servo unit from Japan, adopts Renishaw LP2DD precision probe from UK, Shangyin precision rolling line rail and ball screw, Heidenhain encoder from Germany, meanwhile, in order to ensure the dimensional accuracy of the machining tool, the rotary axis of the machine tool carries out the full closed-loop control of the double DD direct drive, which ensures the machine tool’s superior performance and working accuracy.

- The machine tool adopts fully closed appearance (front movable sliding door, the right side and the back with maintenance door), hand-held electronic handwheel, special start-stop button and foot switch, configuration of automatic cooling system and coolant filter tank, configuration of automatic lubrication device and suction mist interface, alarm buzzer, configuration of the electrical box cooling air-conditioning, so that the machine tool operation, maintenance, maintenance changes are simple and convenient.

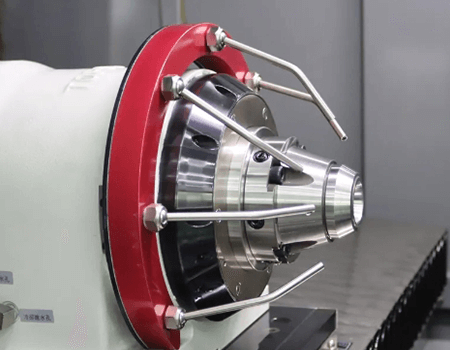

- 5-axis CNC tool grinder with dd direct drive spindle and thebearing is NSK precision spindle bearing, equipped with precision chuck and matching W25 precision collet, and the workpiece is pneumatically

Applications

- The 5 axis tool grinding machine QD580 is a tool grinding center with excellent performance, suitable for producing or resharpening milling tools, drilling tools, forming tools, and so on.

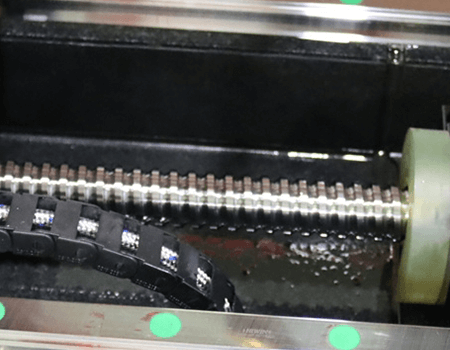

Precision screw: Imported high-precision roller Ball screw, smooth running

Marble bed: Improved shock resistance and stability

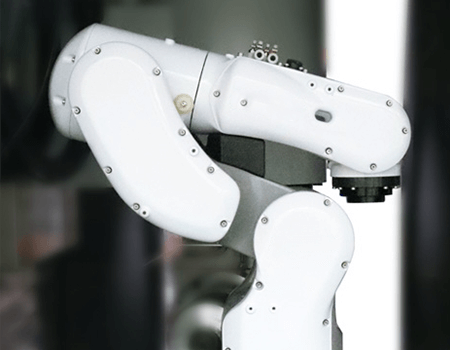

Mechanical arm: Different loading and unloading robots can be built-in according to the processing needs (optional).

Adopting Italian Mapos precision probe, can automatically measure the length of the workpiece and helix inclination, and length deviation is automatically compensated.

The grinding machine adopts high-precision, direct-drive frequency conversion electric spindle, and the spindle has two sets of grinding wheel flanges, each set of flanges can be loaded with 2~4 grinding wheels at the same time, and according to the grinding process, the grinding wheel set can be changed quickly, which can fully meet the needs of various tool grinding.

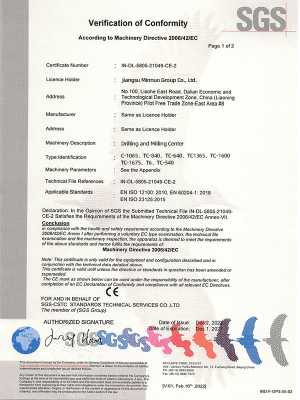

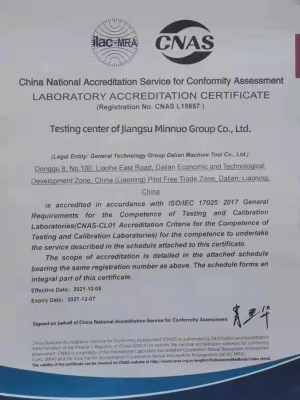

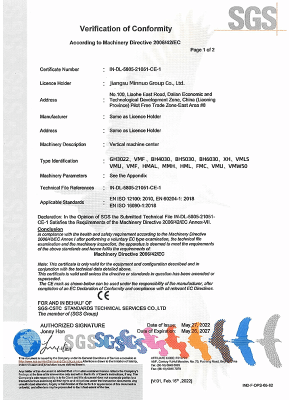

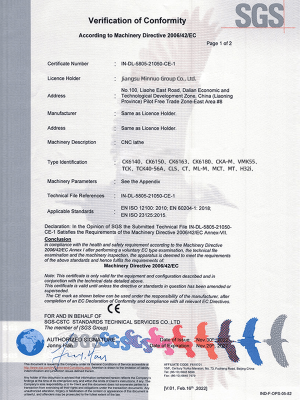

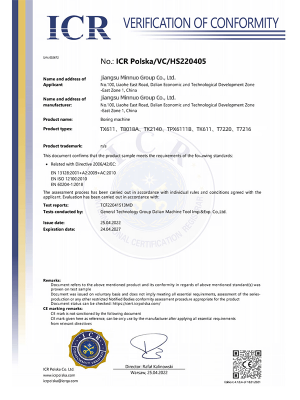

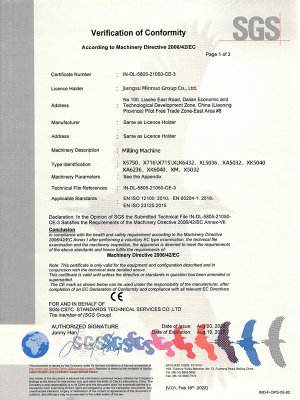

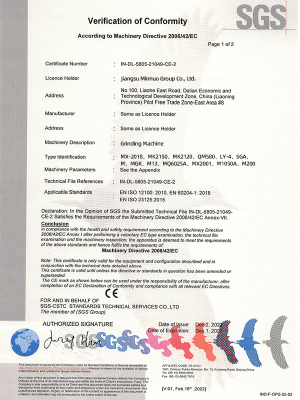

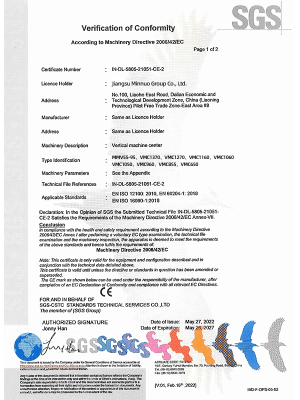

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com