PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

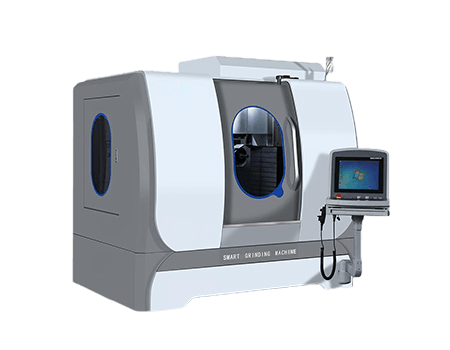

Precision Manual Tool Grinder LY-40 Series

Manual tool grinder LY-40 series is equipped with features such as multi-angle rotation of grinding wheel head, beveled ball bearing support for the mandrel set, flexible tool head and precision table, which is specially designed to enhance the efficiency and precision of tool grinding. It is widely used in machining, mold making and aerospace industries for precision grinding of a wide range of tools such as milling cutters, drills, etc., providing users with an efficient and reliable industrial grinding solution.

- Max. grinding diameter: 248mm

- Max. Swing: 250mm

- Table size: 940*135mm

Features

- Grinding wheel head 15° device: The grinding wheel head can rotate 360° in the horizontal plane and has a ±15° bevel angle, making operation at different angles flexible.

- Mandrel set: supported by two pairs of beveled ball bearings, fixed by screw caps and combined with the spindle using the principle of thermal expansion, the surface is coated with grease lubrication, no need for additional lubrication.

- Tool head: light and flexible operation, capable of precise angle adjustment in horizontal and vertical directions, with ASA No.50 and M.T. No.5 stacking and extraction holes at both ends of the spindle to improve grinding efficiency.

- Precise and accurate multi-purpose table: the table can rotate 120°, equipped with ±60° rotary scale, the working head also has 360° steering function, suitable for grinding large milling cutters and other multi-purpose tools.

Applications

- High precision tool grinding machine LY-40 series is suitable for grinding and processing of many kinds of precision tools, such as milling cutters, drills, face milling cutters, etc. It is especially suitable for occasions that require high-precision angular adjustments and processing of complex shapes. Its versatility and precision make it an ideal choice for machining, mold making, aerospace and other industries.

Specification | Unit | LY-40 | |

Max. grinding diameter | mm | 248 | |

Max. swing | mm | 250 | |

concentric distance | mm | 700 | |

Distance from tailstock to working head | mm | 580 | |

Push-out hole | one end | MT.No.5 | |

other end | ASA No.50(or B & S # 12) | ||

Table bed width | mm | 135 | |

Table bed length | mm | 940 | |

Left/Right Movement Distance | mm | 400 | |

Micro-adjustment angle | ±10° | ||

Bed Rotation Angle | ±60° | ||

Grinding wheel forward and backward travel distance | mm | 250 | |

Grinding wheel lifting and moving distance | mm | 250 | |

Grinding wheel rotation angle | 360±10° | ||

Grinding wheel tilt angle | 30(±15°)/180(±90°) | ||

Min. distance between mandrel and bed surface | mm | 50 | |

Max. distance between mandrel and bed surface | mm | 300 | |

Wheel speed | rpm | 2600,3700,6200rpm | |

Grinding wheel motor | KW | 1.1KW(1 1/2HP) 2 poles | |

Net weight | kg | 950kg | |

Packing Size | mm | 1450 x 1200 x 1550 | |

Shroud Support Rod (Small) | Thimble Socket |

Guide Bar Sliding Block | Hex Wrench Set |

Grinding wheel socket retaining wrench | 1/8″ Grinding Wheel Washers |

Split Guide | 4″ Extension Rod |

T-hex head wrenches | 4″ Extension Rod Socket Set |

Grinding Wheel Removal Wrenches | Belt 5M530 |

Trimming guide bar | Tension screw with washer |

Wheel guard | Toolpost |

Face milling cutter grinding device | Workhead indexing device |

Circular grinding unit (Circular 1) | Drill grinding unit |

Cylindrical grinding unit (Cylindrical 2) | Collet chuck |

Cylindrical grinding unit | Cooling device and water tray device |

Spiral angle grinding unit | Dust collector |

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com