PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

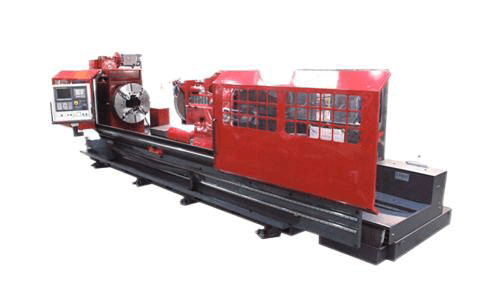

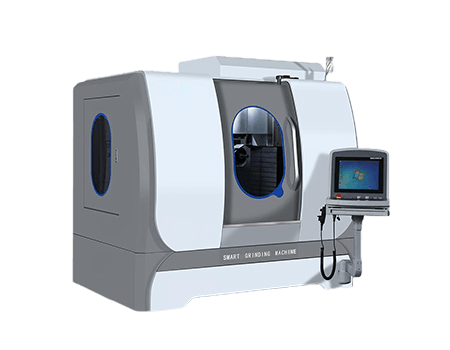

Precision Oilfield Tool Grinding Machine

Large CNC oilfield tool grinder is a grinder product specially developed for oilfield tools. It is characterized by high degree of generalization and modularization, high rigidity, high efficiency and high adaptability. The key outsourcing parts are all imported brand names. The numerical control system adopts the original imported Japanese FANUC company’s FANUC Oi-MD numerical control system, which has a very powerful control function and high stability and advancement, and it can complete all kinds of control of the machine tool.

- Max. grinding diameter: 1118(44")mm

- Min. grinding diameter: 280(11")mm

- Max. workpiece weight: 5T

Specifications | Unit | MKY13110 |

Max. grinding diameter | mm | 1118(44″) |

Min. grinding diameter | mm | 280(11″) |

Max. workpiece weight | ton | 5 |

Spindle speed | rpm | 10~100 |

Power of workpiece motor | kW | 18.5 |

Power of grinding-wheel motor | kW | 18.5 |

Machine weight of 3 meters | Kg | 15100 |

Add weight per meter | Kg | 1200 |

Machine outline size of 3 meters | L*W*H | 9300*3300*2000 |

Features

Oilfield tool grinding machine adopts integral layout, the moving mechanism and workpiece are centrally arranged not only to recover the coolant well, but also to make the operation pleasant. The upper part of the linear guideway is equipped with a traveling guard, which can safely and reliably protect the guideway and has the advantage of good environmental protection performance.

- Bed: The machine tool adopts integral layout structure, the structural design of the bed adopts the latest well structure, fully considering the deformation factor caused by the load bearing, in order to ensure the geometric accuracy of the bed, the bed has been designed by the finite element method, the layout of the fascia board is reasonable, and the material is made of high quality gray cast iron with high grade, which has high rigidity and stability.

- Headstock: The headstock is driven by AC frequency conversion motor, which is characterized by large starting torque and good low-speed performance; meanwhile, the AC frequency conversion motor can economically and smoothly adjust the rotational speed so that the workpiece speed can be steplessly adjusted within the set range. It can be equipped with double chucks at the same time to realize the loading of special parts. The synchronous belt drive can effectively reduce the impact of vibration on the grinding accuracy, and the belt adjustment is equipped with a tensioning device, which can easily adjust the belt tension. The headstock has a wide range of variable speed, high load capacity, high precision and good precision retention.

- Tailstock: Tailstock consists of upper and lower bodies, double-layer tailstock is convenient for adjusting the accuracy of two top horizontal directions. The whole tailstock body along the longitudinal movement of the workpiece bed for manual and grinding wheel frame drive mode, tailstock spindle center and headstock spindle center in the tailstock moving the entire length of the tailstock with good accuracy. Tail frame upper body is equipped with a sleeve, precision live top, sleeve fast and slow moving mechanism; machine tool tailstock sleeve taper hole MT 5. The machine tailstock has the characteristics of high precision, strong bearing capacity, long maintenance cycle and reliable work.

- Grinding wheel holder: one of the core components of the grinding machine, its rotary accuracy and smoothness of movement directly affect the grinding quality of the surface of the workpiece. The grinding head spindle adopts six-cavity dynamic and static pressure bearing, which is characterized by high rigidity and high precision. The grinding wheel chuck adopts concave flange structure, which avoids deflection and deformation of the spindle during powerful grinding, affecting the surface quality of the workpiece, and can effectively eliminate the generation of spiral grain. The rotary accuracy of the grinding wheel is well guaranteed to ensure the high precision and quality of the workpiece to be ground. The transverse movement of the grinding wheel holder (X-axis) is accomplished by the AC digital homogeneous motor driving the ball screw, which can realize the grinding of cylindrical, conical and any curved roller surfaces as well as the rapid movement, continuous transverse feeding and cyclic feeding.

- Transverse feeding system: The transverse movement (X-axis) of the grinding wheel holder is completed by AC digital servo motor driving ball screw, which can realize cylindrical grinding as well as rapid movement, continuous transverse feeding and cyclic feeding, etc. The transverse guideway of the grinding wheel holder is a linear guideway with rolling motion. The transverse guideway of the grinding wheel holder is the rolling motion of linear guideway, which has a particularly small coefficient of friction, so that there will be no idling and slipping phenomenon during micro-feeding, and the feeding accuracy is guaranteed for a long time. The transverse feeding is driven by AC servo motor through ball screw, with high sensitivity and smooth running.

- Longitudinal feeding device: The longitudinal movement of the grinding wheel holder (Z-axis) is completed by the AC digital homogeneous motor driving the ball screw, which can realize cylindrical grinding as well as rapid movement, continuous transverse feeding and cyclic feeding, etc. The longitudinal movement of the grinding wheel holder is a linear guideway. The longitudinal guideway of the grinding wheel holder is a linear guideway with rolling motion, the coefficient of friction is particularly small, and there is no idling and slipping phenomenon during micro-feeding, which ensures the feeding accuracy for a long time. The longitudinal feeding is driven by AC servo motor through deceleration and ball screw, with high feeding sensitivity and smooth operation.

Applications

- Oilfield tool grinding machine is used in oilfield and tool industry, which can complete the grinding of cutting tools such as oilfield pipes, spiral stabilizers, long shafts, reamers, fine turning tools, drills and so on.

Detailed drawings

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com