PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

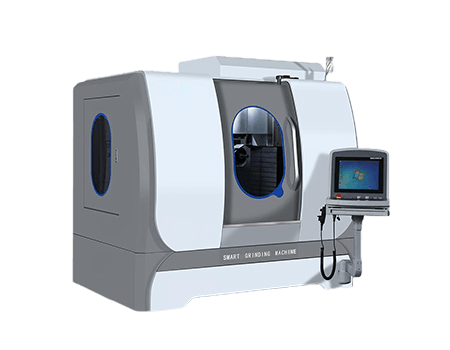

Universal Large Tool Grinding Machine MQ6025A Series

Universal tool grinder MQ6025A is an improved T-tool grinder with better performance. It can sharpen common tools such as reamer, milling cutter, slotted hob, broach, gear shaper and various special tools in addition to grinding outer circle, inner net plane and sample plate etc. The processing range is wide. This machine is suitable for sharpening high speed steel, carbide or other materials.

- Swing dia.of workpiece: 250mm

- Table size: 940*135mm

- Longitudinal travel of table: 480mm

Specifications | Unit | MQ6025A | |

Swing dia.of workpiece | mm | 250 | |

Distance between center | mm | 700 | |

Table size | mm | 940*135 | |

Longitudinal travel of table | mm | 480 | |

Swing angle of table | ° | 120(60) | |

Max. travel of wheel head | mm | 225 | |

Wheel center line of the min distance between the top | mm | 50 | |

Wheel center line of the max distance between the top | mm | 265 | |

The max movement in the vertical direction | mm | 270 | |

Wheel center line up to the top | mm | 200 | |

Wheel center line down to the top | mm | 65 | |

Swing angle of wheel head in horizontal pline | ° | 360 | |

Swing angle of wheel head in vertical pline | ° | 30(±15) | |

The end taper of the spindle |

| MT3# TAPER ANGLE | |

Grinding head motor power 50Hz | Power | KW | 0.85/1.1 |

Speed | rpm | 1400/2800 | |

The speed of grinding head | rpm | 3010/6010 | |

The Motor of Cylindrical grinding attachment:50Hz | Power | KW | 0.25 |

Speed | RPM | 1400 | |

The size of the machine | mm | 1650*1150*1500 | |

The weight of the machine | kg | 940 | |

Features

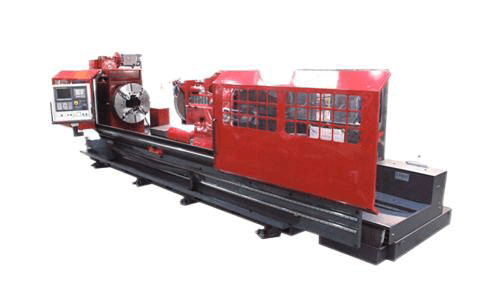

Conventional manual cylindrical grinder is characterized by high cutting precision, high rigidity and high efficiency. It is suitable for grinding cylindrical and conical workpieces.

Manual cylindrical grinding machine composition machine tool workpiece, external grinding wheel, internal grinding wheel, oil pump and cooling pump are driven by independent motors.

- The universal tool grinder table is supported on preloaded ball guides for smooth running and can also be manually speed-regulated.

- The grinding wheel holder of the machine is flexible and can be adjusted in two degrees of space, and the working head can be rotated in two directions, which is convenient for installing all kinds of tools and fixtures.

- The bed is a box-shaped overall structure of the casting, the upper front of a set of longitudinal V-shaped guideway and flat guideway; in the back of a set of transverse V-shaped guideway and flat guideway. The longitudinal guide rail is equipped with a worktable. The transverse guide rail is equipped with a transverse drag plate, the left side of the bed door and the rear door is equipped with electrical components.

- The worktable is divided into two parts: the upper worktable and the lower worktable. The lower worktable is mounted on the longitudinal guideway of the bed, and the guideway is equipped with cylindrical rollers, which enables the worktable to be moved quickly in a lightweight and even manner. The table can be operated by 4 handwheels for forward and backward movement, which is convenient to maneuver the table for grinding in different positions.

- The transverse drag plate is mounted on the transverse rails of the bed with cylindrical roll pins between the rails. The transverse drive is driven by a handwheel through a trapezoidal screw and nut. One turn of the handwheel is 3mm, and one small frame is 0.01mm. Since the handwheel is mounted on the same screw, it can be operated from both the front and the back of the machine. On the transverse drag plate is equipped with a grinding head holder and lifting mechanism, shaking the handwheel, the grinding head holder to do transverse feeding.

- The grinding head motor adopts the standard type A1-7132 motor. The parts set and become, the casing and grinding tool shell cast into a whole; motor stator has internal pressure mounting changed to external pressure mounting, using a miniature triangle belt to drive the grinding head spindle rotation. Both ends of the cone of the grinding head spindle can be mounted on the grinding wheel for grinding. The speed is 4200 rpm and 5600 rpm. The motor of the grinding head can be operated in forward and reverse direction according to the need of grinding, which is controlled by the steering selector switch of the maneuvering board. The lifting mechanism of the grinding head adopts a cylindrical guide rail, guided by oblique keys. The grinding head lifting and lowering is divided into two kinds: manual and motorized. Manual. Turn the handwheel, through the turbine vice deceleration and a pair of spur gears to speed up, through the nut, screw to make the guide rail up or down. When motorized, press the lifting electric button (motorized button on the manipulation board), the motor starts, decelerates through a gear difference, connects the screw through the bonding sub, and makes the guideway rise or fall through the nut.

Applications

- The universal tool grinder is suitable for sharpening high-speed steel, carbide or other materials, and is also convenient for grinding cylindrical, flat groove and molding surfaces. If equipped with special accessories, it can also grind all kinds of gears, worm gear hobbing cutters, forming cutters, ball-end milling cutters, twist drills, taper reamers and so on.

Standard accessories:

- Grinding Wheel Shield

- Left and right tailstock

- Arbor

- Grinding Wheel Corrector

- Universal Grinder

- Foot

- Cutter tooth support

- Tie rods

Optional accessories:

Accessory Name | Quantities |

Universal grinder | One. |

Left and right tailstock | One each |

Grinding Wheel Corrector | One set |

Grinding wheel guard | Two |

Grinding Center Shaft | One |

Tool tooth support | One set |

Arbor φ22, φ27, φ32 | One each |

Tie rods M24 (Nt50) | One. |

Hexagonal wrench | One set. |

Foot | Three. |

Tool box | One. |

Grinding wheel | Two. |

2#top2# | One. |

Indexing plate (24 equal parts) | One. |

Reducing sleeve | Three. |

Grinding Wheel Extension Shaft | One. |

Center gauge | One. |

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com