PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

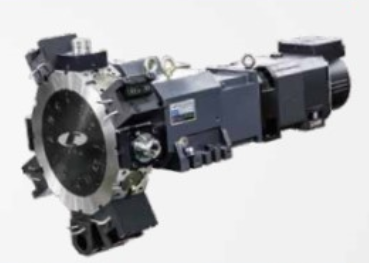

High-speed Dual Spindle Mill-turn Machine CTX200S

High-speed dual spindle mill-turn machine CTX200S is a very compact machine with a footprint of less than five square meters, making the best use of available space in the workshop. The twin-turret, twin-spindle CNC lathe with a fixed headstock is compact, versatile and fast for combined turning, milling and drilling of small-sized parts. The robust cast-iron construction, the sturdy components such as the screws, linear guides, the power turret and the spindles, as well as the powerful spindle motors, make it a perfect choice for the most demanding applications.

- Max work piece length: 450mm

- Max. processing diameter (disc): 280mm

- Max. bar capacity: 49mm

- Max. swing over bed: 700mm

Features

The CTX200S is a high-precision, high-rigidity, high-efficiency automated machining equipment for precision machining of various metal parts. The double spindle design allows the machine to machine two workpieces at the same time, thus significantly increasing productivity and reducing production time by up to 75%. Previously required 2 ~ 3 or even more ordinary equipment to complete the processing, now only need a composite processing machine can be easily completed can be realized 24 hours of continuous non-stop work, reduce manual intervention, safe and reliable to reduce labor costs, a one-time investment, a year or so back to the capital. It can also reduce the operation time by 75%, minimize the time and manpower consumption relative to the conventional operation, the consistency of product processing is greatly improved and stable.

- Taiwan roller type linear guide, with high load capacity and good anti-wear performance, can ensure CNC machine tools to maintain accurate positioning and stable motion performance in long time operation.

- High-speed, high-precision, high-rigidity spindle unit: the spindle is the heart of the CNC machine tool, high-speed operation can provide faster machining efficiency, high-precision to ensure the quality of the machined parts, and high rigidity means that when subjected to the cutting force to maintain a very small deformation, which is essential to improve machining accuracy.

- High-power Y-axis motor: It can provide stronger driving force to support heavier cutting tasks and faster feed speeds, effectively improving productivity.

- Pre-embedded lubrication system: Ensures continuous and uniform lubrication of all sliding parts, reducing maintenance time, prolonging the life of the machine and minimizing downtime.

- High Rigidity Integral Slant Bed: The design of slant bed itself is an effective way to enhance the rigidity of the machine tool, which can better resist all kinds of stresses generated during the cutting process and ensure that the machine tool maintains stable high performance for a long time.

Applications

- All machining in a single clamping – Further pursuit of high-speed, high-precision and powerful combined machining capability.

- High-speed dual spindle mill-turn machine CTX200S is capable of machining a wide variety of large and long workpieces for a wide range of applications in the aerospace, energy, shipbuilding, medical and other industries. The modular concept and highly versatile options offer a wide range of machining possibilities, from general-purpose turning to the complete machining of complex parts.

| PARAMETERS | UNIT | CTX200S |

| Max. swing over bed | mm | 700 |

| Max. swing over cross slide | mm | 350 |

| Max. Work piece length | mm | 450 |

| Max. Bar capacity | mm | 49 |

| Max. Processing diameter | mm | 280 |

| Spindle bore | mm | 65 |

| Spindle speed | rpm | 50-3000 |

| Spindle power | kw | 11 |

| Sub-spindle bore | mm | 65 |

| Sub-spindle speed | rpm | 50-3500 |

| Sub-spindle power | kw | 15 |

| Chuck type | 8 inch hydraulic | |

| Turret type | Y axis living turret | |

| Tool holder size | BMT45 | |

| Tool size | mm | 25X25/Φ40 |

| X axis travel | mm | 200 |

| Z axis travel | mm | 550 |

| Y axis travel | mm | ±45 |

| Net weight | kg | 4250 |

| Machine dimension(LxWxH) | m | 3.4X2.0X2.2 |

Spindle: Equipped with a highly productive, high-precision mechanical spindle.

High speed – Adopting high-speed, precision matched bearings, rigid or elastic preload structure, can obtain high speed, so that the tool can play the best cutting effect.

High Precision-High precision bearings and high precision parts manufacturing are sufficient to ensure that the radial runout of the 7:24 taper hole to the mounting base surface is within 0.005MM.

High Efficiency – The ability to change the speed in a continuous fine-tuning manner allows instant control of the cutting speed throughout the entire machining process to maximize machining efficiency.

Low noise – After dynamic balancing test, the grade reaches G1 or 60.4 (1S01940-1), and the spindle has the advantage of low noise under high-speed rotation.

Sub-spindle: High-speed, high-power electric spindle

Space-saving – The space for installing belts and gears is eliminated on the motorized spindle products, which reduces the intermediate transmission loss and saves a lot of space at the same time.

High precision – The digitally controlled motor spindle with fast response speed and high rotary accuracy can work well in high-precision machining situations.

High efficiency – The use of the motorized spindle as the core of the drive greatly reduces the machining time to a quarter of the usual time.

High quality – The quality of machining with electric spindles is much better without further processing and polishing.

Servo power turret

Quick indexing and locking.

High rigidity, stability and low noise.

Select the nearest fool through two-way positioning, and confirm the loosening and locking status with double inductive switch.

The cutter head can select 6-8-10-12 bits

Integrated operation station

Two piece connector and hydraulic locking are used to ensure the rigidity of the turret.

The power turret can reach 5000/6000 rpm at most, which can be completed Milling, cutting, tapping and other processes .

BMT cutterbed 1809 system is adopted.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com