PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

High-speed Mill-turn Machine TCK50M/TCK50Y/TCK25Y

The TCK50M(Y)/TCK25Y series are compact, high-speed mill-turn machines that take up a minimum of less than five square meters of space, making the most of the available space in the shop floor Dual turret, dual spindle CNC lathes with a fixed spindle box are compact, versatile, and fast, and allow for combination turning, ironing, and drilling of small-sized parts Sturdy cast-iron construction, sturdy components such as the screws, linear guides, power turret, and spindles, as well as a powerful spindle motor. These adopt advanced CNC technology and is capable of realizing turning and milling processing of complex parts with a wide range of applications.

- Max work piece length: 400/700/1500mm

- Max. processing diameter (disc): 350/350/350mm

- Max. bar capacity: 54/74/74mm

- Max. swing over bed: 560mm

Features

High-speed mill-turn machine TCK50M/TCK50Y/TCK25Y high speed turning and milling machine is a machine tool equipment that combines high precision, high efficiency and high stability.

- High-precision Taiwan linear guide: Provides high motion precision and high rigidity to ensure precise positioning of the machine tool during machining, thus ensuring the dimensional accuracy and surface finish of the machined parts.

- High-speed spindle unit: Capable of improving machining efficiency while maintaining high accuracy.

- High-strength cast iron: It can increase the overall stability of the machine tool and prolong its service life.

- Automatic centralized lubrication: Ensures good lubrication of all sliding parts of the machine tool during long-time operation, reduces maintenance work, lowers the failure rate, and also helps to improve the machine tool’s motion performance and machining accuracy.

- Optional power turret: adds more flexibility to the machine, enabling it to perform more complex machining tasks, increasing productivity and machining capacity.

Applications

- The machine is suitable to process all kinds of small and middle-sized shaft and plate work piece, and could also turn various threads,circle arc, circular cone, inside and outside surface of revolved body.This machine is widely used in sanitary, valve, electrical appliance,instrument, auto mobile, motorcycle, bearings and so on.

PARAMETERS | UNIT | TCK50M | TCK50Y | TCK25Y |

Max. swing over bed | mm | 560 | 640 | 510 |

Max. swing over cross slide | mm | 300 | 380 | 150 |

Max. Work piece length | mm | 400/700/1500 | 400/700/1500 | 150 |

Max. Bar capacity | mm | 54/74/74 | 54/74/74 | 44 |

Max. Processing diameter | mm | 350/350/350 | 300/450/450 | 250 |

Spindle bore | mm | 66/86/86 | 66/86/86 | 56 |

Spindle speed | rpm | 50-3000 | 50-3000 | 50-4500 |

Spindle power | kw | 11/15/15 | 11/15/15 | 5.5 |

Chuck type |

| 10 inch hydraulic | 10 inch hydraulic | 6 inch hydraulic |

Tail stock type |

| hydraulic type | hydraulic type | hydraulic type |

Turret type |

| living turret | living turret | living turret |

Tool holder size |

| BMT45 | BMT45 | BMT40 |

Tool size | mm | 25X25/Φ32 | 25X25/Φ32 | 20X20/Φ25 |

X axis travel | mm | 240/260/260 | 240/260/260 | 135 |

Z axis travel | mm | 500/800/1500 | 500/800/1500 | 370 |

Y axis travel | mm |

| ±45 | ±30 |

Quill diameter | mm | 70/90/90 | 70/90/90 |

|

Quill travel | mm | 80 | 80 |

|

Net weight | kg | 3300/4000/5000 | 3400/4100/5100 | 2500 |

Machine dimension(LxWxH) | m | 2.6/3.4/4.1×2.0x2.0 | 2.6/3.4/4.1×2.0x2.0 | 1.8×1.5×2.0 |

Hydraulic chucks:

wedge-shaped through-hole chucks, fast clamping and loosening of workpieces under hydraulic pressure, fast clamping speed and high precision.

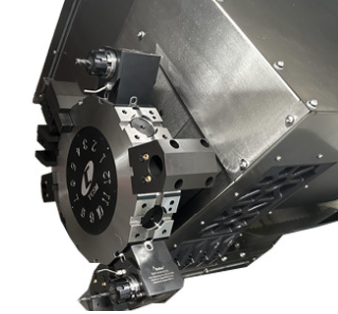

Power Turret:

Servomotor-driven turret with two-way fast tool selection.

Adoption of high-precision triple end gear locking.

Turning, milling and drilling in one unit by means of power tool holder.

Radial angle machining through the power turret.

High-speed spindle unit:

Adopting high-precision spindle bearing set and spindle with precision assembly and dynamic balance test to ensure high spindle precision, low noise and strong rigidity.

High precision Taiwan linear guide

Screws and nuts are processed, ground, assembled and QC’d in the constant temperature workshop, which can guarantee the stability of its high precision. Small friction coefficient by using linear rail, fast moving speed and high precision.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com