PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

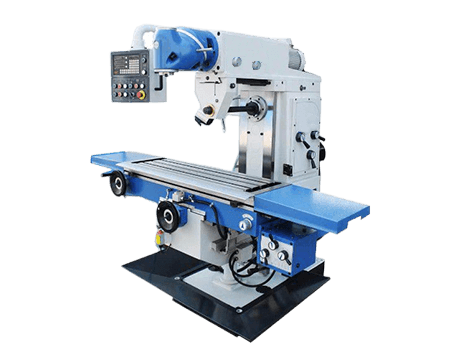

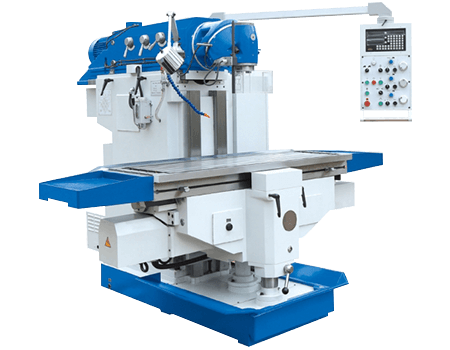

Conventional Universal Milling Machine XA6236 Series

Conventional universal milling machine XA6236 is a powerful metal cutting machine. The machine tool has strong rigidity, wide range of feed speed change, and can withstand heavy load of chips. The spindle taper hole can be directly or through the attachment to install a variety of cylindrical milling cutter, circular slice milling cutter, molding milling cutter, end milling.

- Table size: 1250*360mm

- Table travel (longitudinal/transverse/vertical):1000/320/500mm

- Spindle taper: 7:24 ISO40(vertical) /ISO50(horizontal)

Parameter | Unit | XA6236 |

Spindle taper |

| 7:24 ISO40(vertical) /ISO50(horizontal) |

Distance from vertical spindle hole center to column surface | mm | 350-850 |

Distance from vertical spindle end face to table surface | mm | 210-710 |

Distance from horizontal spindle center to table surface | mm | 0-500 |

Distance from the center of horizontal spindle to the lower surface of ram | mm | 175 |

Spindle speed range | r/min | (11step)35-1600(vertical) |

(12step)60-1800(horizontal) | ||

Table size | mm | 1250*360 |

Table travel (longitudinal/transverse/vertical) | mm | 1000/320/500 |

Table longitudinal/horizontal motorized feed rate | mm/min | 15-370(8step)(Fast540) |

Table vertical motorized lifting speed | mm/min | 590 |

Table T-slot number/width/spacing | mm | 3/18/80 |

Main drive motor power | kw | 2.2(vertical)4(horizontal) |

Table motorized feed motor power | W | 750 |

Motor power of lifting table lifting and feeding | W | 1100 |

Cooling pump motor power | W | 90 |

Net weight | kg | 2400 |

Dimension | mm | 2220*1790*2040 |

Features

Universal milling machine has stable quality, easy operation and reliable performance. Horizontal milling machine can be used to process various flat surfaces, inclined surfaces and grooves with various cylindrical milling cutters, circular slice milling cutters, angle milling cutters, molding milling cutters and end milling cutters. If you use the appropriate milling machine accessories, can be processed gears, cams, arc grooves and helical surface and other special shapes of the parts, configuration of universal milling head, round table, indexing head and other milling machine accessories, the use of boring tool bar can also be used for small and medium parts of the hole processing. With the addition of vertical milling head, the cutting process can be carried out by vertical milling cutter (vertical milling head is a special accessory), which can further expand the scope of use of the machine tool. This machine tool is suitable for all kinds of machining industry.

- Longitudinal tableThe longitudinal table is driven by a longitudinal screw to move longitudinally on the guideway of the rotary table to feed the workpiece longitudinally on the table. The T-slot on the table is used to install fixtures or workpieces.

- Horizontal worktable horizontal worktable is located on the horizontal guideway above the lifting table, can drive the longitudinal worktable together for transverse feed.

- TurntableThe turntable can turn the longitudinal table in the horizontal plane at a certain angle (±45°), in order to mill spiral grooves and so on. Horizontal milling machine with turntable is called horizontal universal milling machine.

- Lifting platform can drive the whole table along the vertical rail of the bed up and down to adjust the distance between the workpiece and the milling cutter and vertical feed. The base is used to support the bed and the elevating table, and contains cutting fluid.

Applications

There are two kinds of transmission mechanism: vertical spindle and horizontal spindle. Vertical spindle can be used for both vertical and horizontal milling, and it can mill plane and inclined surfaces, etc. Configuring the corresponding machine mechanism, it can also process spiral groove and groove. The two-section rotary milling head can make the spindle rotate and adjust at any angle, and one clamping can complete the machining of complex parts such as multi-angle and multi-face.

Horizontal spindle taper hole can be directly or through the accessory installation of a variety of cylindrical milling cutter, circular slice milling cutter, molding milling cutter, end milling cutter and other cutting tools, suitable for machining a variety of small and medium-sized parts of the plane, inclined surfaces, grooves, holes, gears and so on.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com