PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

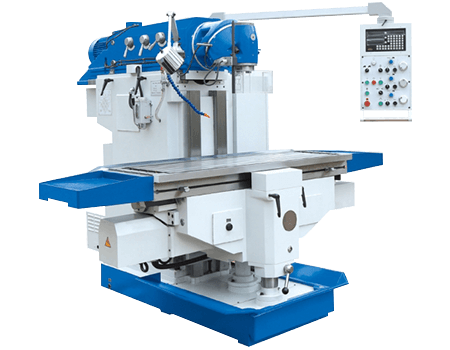

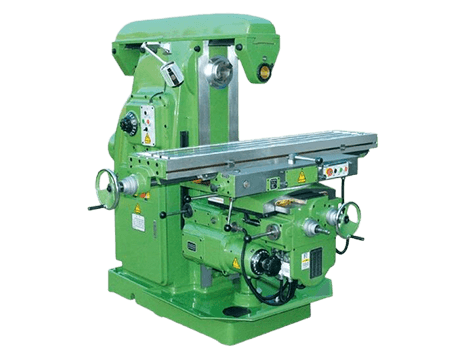

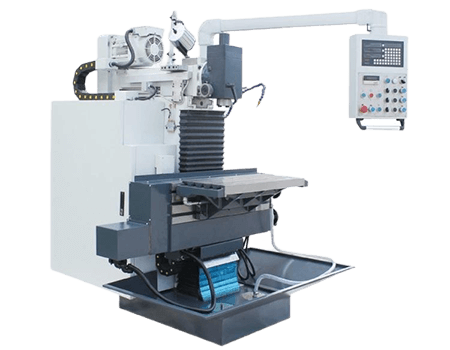

Universal Rotary Head Milling Machine Series

Universal rotary head milling machine series is a kind of vertical milling machine with strong structural rigidity, easy operation and high cost performance. Equipped with a universal rotary head, it can realize multi-angle milling and possesses strong machining capability, which is capable of high-speed and bearing heavy loads of cutting work and gear machining.

- Table size: 1500x360mm

- Table stroke: 1000x320x500mm

- T-type slot numbers / width /space: 3/18/80mm

Specifications | Unit | X6436 | X6432 |

Table size | mm | 1370×360 | 1370×320 |

mm | 1500×360 | 1500×320 | |

Table stroke | mm | 1000x320x500 | 1000x300x500 |

T-type slot numbers / width /space | mm | 3/18/80 | 3/14/60 |

Distance from spindle axis to table surface | mm | 0-400 | 0-400 |

Spindle taper |

| ISO50 | ISO40 |

Spindle speed range(steps) | rpm | 48-1660(V) | 28-1660(V) |

rpm | 60-1800(H) | 40-1300(H) | |

Milling head swivel range | ° | 360 | 360 |

Spindle motor power | KW | 4 | 3 |

Overall dimensions | mm | 2070x2025x2020 | 2020x1710x1994 |

Machine weight | kg | 2480 | 2100 |

Features

The drilling and milling machine has advanced and reasonable structure, light and flexible operation, easy maintenance, and can generally meet the requirements of IT8 level accuracy and roughness.

- The milling head of this universal milling machine can be rotated to any angle, both vertical and horizontal; the milling head 6-step gear speed change, use in drilling, milling plane, reaming and trimming end face and other forms of processing.

- The main spindle adopts energy consumption brake with large braking torque and stops quickly and firmly.

- The worktable Y, Z direction is a wide rectangular guideway, the stability is stronger. The table is motorized feeding in X, Y and Z directions, and the X, Y and Z guideways are ultra-audio quenched and precision ground to be more wear-resistant.

- The design of the spindle with two joints makes it easy to realize vertical and horizontal milling conversion and the combination of any angle in space, and makes the rigidity higher than that of the three joints. The two joints are equipped with precise positioning pins to ensure the precise positioning of vertical and horizontal milling conversion, which is more convenient for operation.

- The parts of this universal rotary head milling machine that are easy to wear are equipped with an adjustment device to eliminate the gap, which ensures the precision of the machine tool and the smoothness in the work.

- The manual lubrication device of this milling machine can force lubrication effect on the screw and guide rail, and it is more convenient to inject oil.

Applications

- The taper hole of the spindle of this universal milling machine series can be installed with various kinds of cylindrical milling cutters, circular slice milling cutters, molding milling cutters, end milling cutters and other cutting tools directly or through the accessory, which is suitable for machining the flat surface, beveled surface, grooves, holes, gears, etc of all kinds of medium-sized and small-sized parts. It is the ideal processing equipment for machinery making, mold, instrument, meter, automobile, motorcycle and other industries.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com