PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

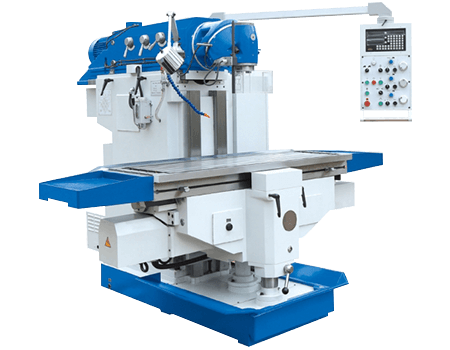

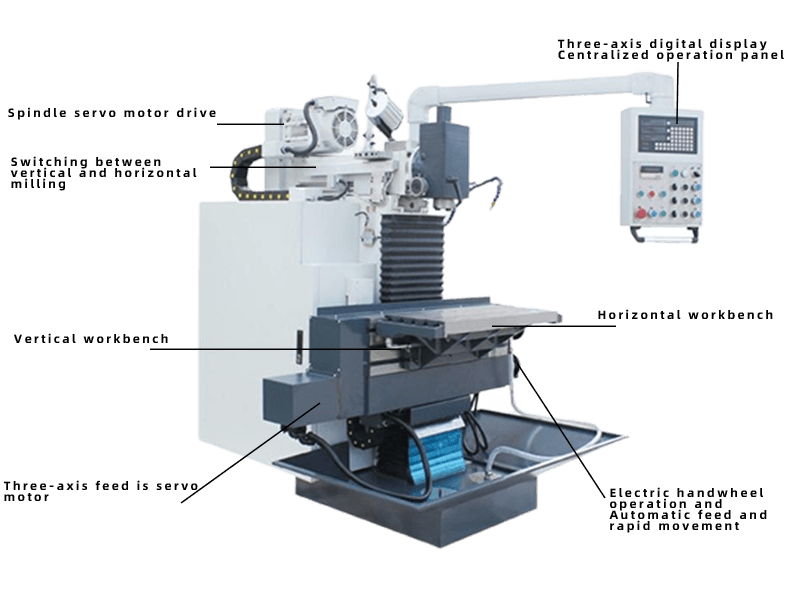

Universal Tool Milling Machine XL8132/40/45 Series

Universal tool milling machine XL8132/40/45 series, is a vertical and horizontal dual-purpose milling machine, double table, can realize multi-functional multi-revolution processing, such as the need for CNC system can be customized.

- Horizontal table size(L × W): 850×450mm

- Vertical table size(L × W): 1190×250mm

- X/Y/Z axes travel: 600/450/450mm

Specification | Unit | XL8132 | XL8140 | XL8145 |

Horizontal table size(L × W) | mm | 750×320 | 800×400 | 850×450 |

T- slots( Number/width/distance) | mm | 5*14*63 | 6*14*63 | 7*14*63 |

Vertical table size(L × W) | mm | 890×225 | 1020×225 | 1190×250 |

T- slots( Number/width/distance) | mm | 3*14*63 | 3*14*63 | 3*14*63 |

Max. table load | kg | 160 | 200 | 300 |

X/Y/Z axes travel | mm | 405/305/400 | 500/400/400 | 600/450/450 |

Spindle taper(H.&V.) | — | NT40 | NT40 | NT40 |

Spindle speeds(H.&V., variable) | rpm | 40-2000 | 40-2000 | 40-2000 |

Stroke of vertical spindle quill | mm | 60 | 60 | 60 |

Feed rate(X/Y/Z axis) | mm/ min | 10-1000 | 10-1000 | 10-1000 |

Rapid traverse(X/Y/Z axis) | mm/ min | 1200 | 1200 | 1200 |

Main motor power | Kw | 3.7 | 3.7 | 5.5 |

Feed motor torque(X/Y/Z axis) | Nm | 7.7/7.7/10 | 7.7/7.7/10 | 10/10/15 |

Machine Weight | kg | 1450 | 1550 | 1750 |

Machine dimensions(LxWxH) | mm | 1500×1700×1800 | 1500×1700×1800 | 1600×1800×2000 |

Features

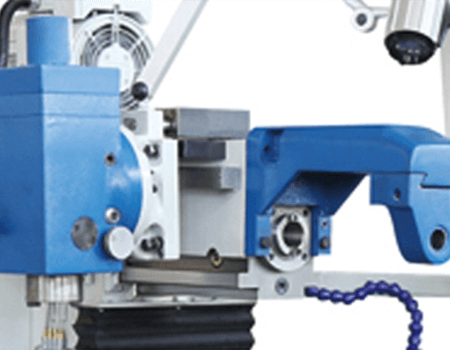

- Dual milling head: the milling head can be used both vertically and horizontally, when installing the vertical milling head, it can be used for milling and drilling, and when installing the horizontal milling head, it can be used for boring by installing the hanger.

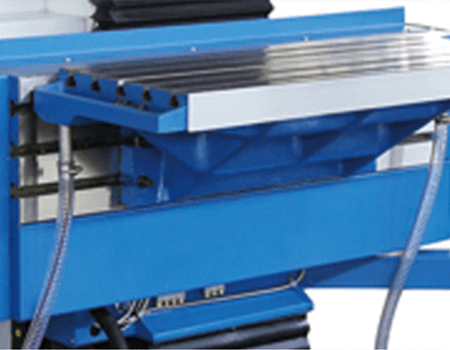

Dual worktable: The milling machine comes with dual worktables, vertical and horizontal.

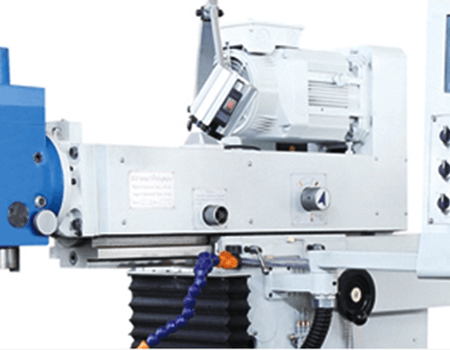

Adopting gear transmission, two gears of infinitely variable speed regulation, spindle speed 40~2000 rpm, wide range of variable speed, to meet the requirements of different materials processing.

X, Y, Z three directions feeding for electronic handwheel feeding, high precision, lightweight and handy, efficiency doubled.

Applications

- CNC facing lathe, through the automatic control of CNC system (FANUC/SIEMENS/GSK/KND,etc) , can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

- CNC face lathe machine CK64 series have a large load capacity, strong rigidity, beautiful appearance, easy to operate to turn various parts of the internal and external cylindrical surfaces, end faces, arcs and other molding surfaces, is the processing of a variety of tire abrasives and large plane discs, a variety of flanges, pipe fittings, valves, pressure vessels, mining machinery, the ring class of parts of the ideal equipment.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com