PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

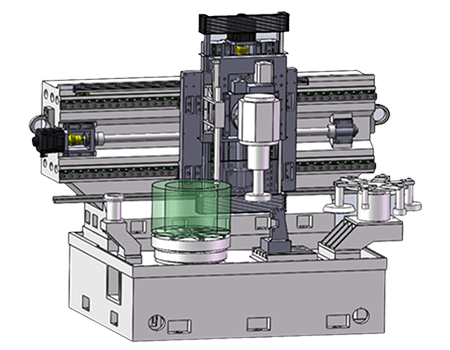

Vertical Single Grinding Head CNC Grinding Machine

Single head vertical CNC grinding machine, with its high-precision CNC system and vertical layout, realizes multi-face precision grinding of external, internal, flat and forming surfaces, which is widely used in automotive, aviation and other industries, suitable for batch processing of complex workpieces, reduces the need for manual labor with its automated operation, improves productivity and safety, and is an indispensable, efficient, flexible, and reliable equipment for precision manufacturing.

- Max. workpiece turning range: φ850mm

- Max. workpiece height: 400mm

- Table diameter: φ800mm

- Workpiece table load: 800kg

Specification | Unit | MGK2860 | MGK2880 | |

Basic parameters | Table diameter | mm | φ600 | φ800 |

Max. workpiece turning range | mm | φ750 | φ850 | |

Max. workpiece height (max. grinding depth) | mm | 400 | 400 | |

X-axis travel | mm | 1500 | 1500 | |

Z-axis travel | mm | 600 | 600 | |

Bore grinding range | mm | φ50~φ200(Hole depth≤200) | φ50~φ200(Hole depth≤200) | |

mm | φ200~φ600 (Hole depth≤400) | φ200~φ600(Hole depth≤400) | ||

Cylindrical grinding range | mm | ≤φ650 | ≤φ850 | |

Workpiece table load | kg | 600 | 800 | |

Working table | Rotation accuracy (axial/radial) | mm | 0.0015 | 0.0015 |

Rotation speed | rpm | ≤200 | ≤200 | |

Grinding wheel spindle | Rotation accuracy (axial/radial) | mm | 0.002 | 0.002 |

Frequency conversion motor power | kw | 11 | 11 | |

Maximum speed | rpm | 7000 | 7000 | |

Number of grinding rods | PCS | 3 | 3 | |

Positioning accuracy | Servo axis positioning accuracy | mm | 0.01 | 0.01 |

| Servo axis repeatability | mm | 0.006 | 0.006 |

X/Z axis | Minimum resolution | mm | 0.001 | 0.001 |

Minimum feed | mm | 0.001 | 0.001 | |

Maximum travel speed | m/min | 10 | 10 | |

Weight of the whole machine | Net weight | kg | 13000 | 14000 |

Total power |

| KVA | 50 | 50 |

Floor space | Length×Width×Height | m | 5×3.5×3.5 | 5×3.5×3.5 |

Features

- The base of the vertical single-head grinder is an integral square structure with a multi-layer mesh rib arrangement for high overall structural strength. The column beam is of high-strength wall plate structure, the bottom surface of the beam is vertically mounted on the base, and the bottom is full circle contact, good contact rigidity and stability.

- The table is driven by a torque motor to realize infinite speed regulation, and the optional Heidenhain angle encoder can realize non-circular grinding, and the spindle of the rotary table is a high-precision closed-type hydrostatic spindle.

- X-axis (grinding head transverse movement) guideway selection of large-size double line rail configuration of multiple sliders, slider selection of heavy preload products, strong load-bearing capacity; Z-axis (grinding head vertical movement) using a medium-sized line rail heavy preload, the product configuration of a number of sliders, X / Z-axis are used in high-power servo motors with high response speed.

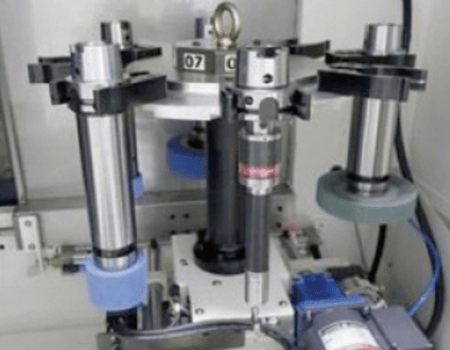

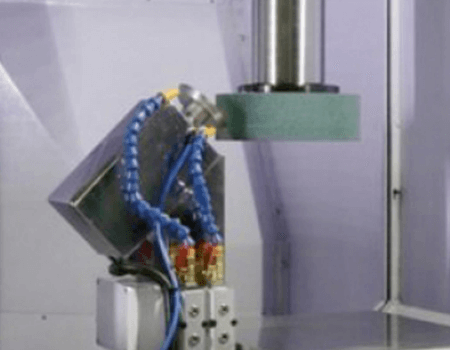

- The spindle is a single vertical spindle, the spindle bearing is NSK imported precision ball bearings, the motor rotor and the spindle are integrated structure with good rigidity, the spindle end face is equipped with ring spraying more suitable for internal grinding, the spindle base is fixed on the CNC turret, the CNC turret is fixed on a vertical slide plate, the spindle can be oscillated with the turret from 0 to 30°, the spindle is equipped with a variety of grinding wheels grinding rods can be mounted on different specifications of the grinding wheels to meet the needs of different internal holes, external diameters and end face grinding needs, outer diameter and end face grinding.

Applications

- Single grinding head vertical CNC grinding machine, drawing on advanced Japanese technology to build its main structure, is specially designed for precision grinding of large rings, disks, bushings and cylindrical parts, ensuring accuracy and high efficiency in the machining process.

- The main applications are in the precision measurement industry, wind power industry, aerospace and machine tool spindles and other related industries.

Vertical single-head CNC grinding machine table travel charts

Grinding wheel spindle detail

Single-head vertical lathe machining diagram

Equipments

Standard Accessories

Closed static pressure turn table

X axis grating ruler

Siemens 828D system

lubricating device for linear guideway and ball screw

Air filtration unit

Single point diamond pen dresser

Fully enclosed guard

Grinding wheel spindle (oil cooler)

Large torque permanent magnet (including water cooler)

Rotary hydraulic station (oil cooler)

Electric cabinet (including air conditioning)

Magnetic roll paper tape cooling water tank

Grinding wheel flange and balance stand

Water gun, air gun

Optional accessories

Roller dresser

Half closed guard

ATC

Automatic measuring device

Electropermanent magnet sucker

Circular arc dresser

Z axis grating ruler

Oil mist device

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com