PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

Double Moving Column CNC Vertical Lathe KD500 KD800 Series

The double moving column vertical lathe combines the stability of a traditional vertical lathe with the flexibility of a moving column lathe. It adopts the moving column structure with box guideway, which enhances the machine’s heavy cutting ability and can precisely control the machining accuracy, which is suitable for highly demanding machining tasks. It is widely used for machining various shaft parts, such as rotary shafts, screws and transmission shafts.

- Max. swing diameter : φ950mm

- Max. turning diameter: φ850mm

- Max. turning height: 500mm

- Chuck in: 32’’

Features

- Movable column structure, solid and stable, with strong heavy cutting ability.

- High power spindle motor, high torque output.

- X-axis three-linear rail layout, greatly improving the rigidity and stability of the machine tool.

- Double chip conveyor rear discharge, high cutting removal efficiency.

- Brake disk can feed two knives at the same time, double guarantee of precision and effect.

Applications

- The double moving column CNC vertical lathe is widely used for machining a variety of shaft parts, such as rotor shafts, screws and transmission shafts. Its double-head structure allows simultaneous roughing and finishing, enhancing machining efficiency. In addition to shaft parts, it is also suitable for the machining of related parts in the electric motor, hydraulic turbine, aviation, mining machinery, metallurgy and machinery industries, etc. It is capable of completing the internal and external cylindrical surfaces, conical surfaces, end surfaces, threads, grooving and other processes. These characteristics make it also widely used in military, automobile, aviation, mold, metallurgy, electric power and other manufacturing industries.

Specification | Unit | KD500 | KD800 | |

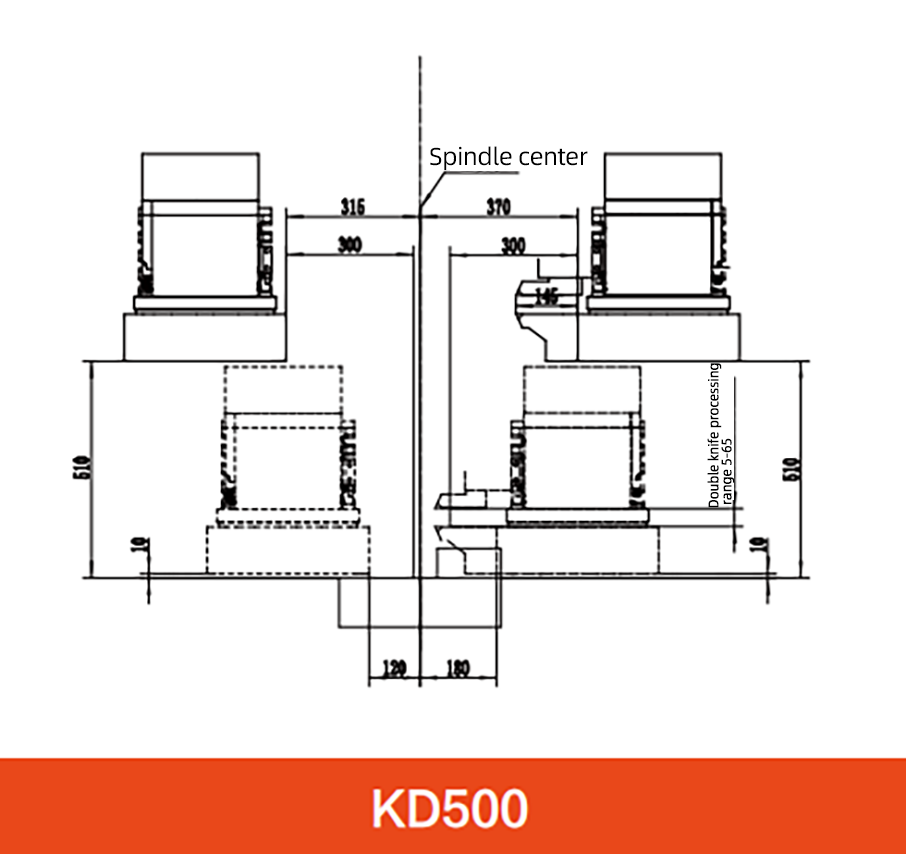

Travel | X axis | mm | 300 | 450 |

Z axis | mm | 500 | 500 | |

Machining capability | Max. swing diameter | mm | φ650 | φ950 |

Max. turning diameter | mm | φ500 | φ850 | |

Max. turning height | mm | 500 | 500 | |

Spindle | Spindle speed | rpm | 100-1000 | 50-300 |

Spindle motor power | Kw | 30 | 22(speed reducer) | |

Arbor outer diameter | mm | φ160 | φ180 | |

Hydraulic chuck + tool holder | Chuck types |

| Hydraulic chuck | |

Calibre | inch | 15’’ | 32’’ | |

Turret station |

| 8-station+8-station | 8-station+8-station | |

Guideway | X-axis rolling linear guide ways |

| 3,width 55mm | box way |

Z-axis rolling linear guide ways |

| 4,width 55mm | box way | |

Accuracy | Repeatable Positioning Accuracy | mm | ±0.003 | ±0.012 |

Positioning Accuracy | mm | ±0.006 | ±0.02 | |

Min. positioning unit | mm | 0.001 | 0.001 | |

Net weight | Kg | 10000 | 12000 | |

Machine dimensions ( L*W*H ) | mm | 2800*2400*2910 | 3450*2550*3250 | |

Turret Travel Diagram (Maximum Machining Outline Drawing)

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com