PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

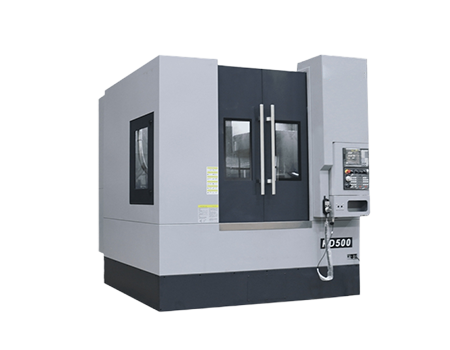

Single Columns CNC Vertical Lathe VTC40/VTC50/VTC60/ VTC70/VTC80A/VTC100A Series

Single-column CNC lathe CK series is a kind of high-precision and high-efficiency CNC machining equipment. It has an upright spindle, a single-column structure, and the table moves in a transverse sliding mode. The lathe adopts all-axis hard-rail structure, and at the same time expands the width and span of the guideway to effectively improve the rigidity of the equipment, which makes the equipment more suitable for heavy-duty cutting.

- Max. swing diameter : φ1200mm

- Max. turning diameter: φ1000mm

- Max. turning height: 1000mm

- Chuck in: 32’’

Features

Single-column CNC vertical lathe for processing and production can simplify the overall production process, the use of which can improve the processing accuracy, to avoid a variety of complex error values, to improve the efficiency of production and processing, but also to improve the stability of the processing, greatly simplifying the complexity of the overall processing and production.

- The design of single-column vertical lathe is relatively simple, with a central column supporting the whole machine structure. The operation of single-column CNC vertical lathe is simple, conforming to the design requirements of ergonomics and low economic cost;

- Due to the more compact structure, this type of machine tool occupies less factory space and is suitable for environments with limited space.

- Adoption of high silent closed protection structure, good rigidity of the whole machine, high machining precision, waterproof and dust proof performance is greatly superior to similar products.

- The whole machine is equipped with leakage and power failure protection device, safe and reliable.

Applications

- Single-column vertical lathe is suitable for small and medium-sized enterprises or processing workshops, especially for those occasions where the processing needs are not particularly complex, or where specific types of parts need to be processed, and it is suitable for processing many types of disks, shafts and ring-shaped parts.

- It is widely used in the fields of railroad, shipbuilding, machinery manufacturing and mold making.

Specification | Unit | VTC40 | VTC50 | VTC60 | VTC70 | VTC80A | VTC100A | |

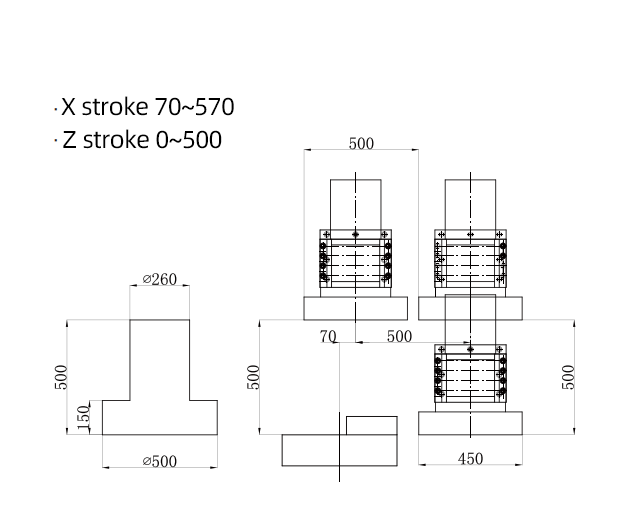

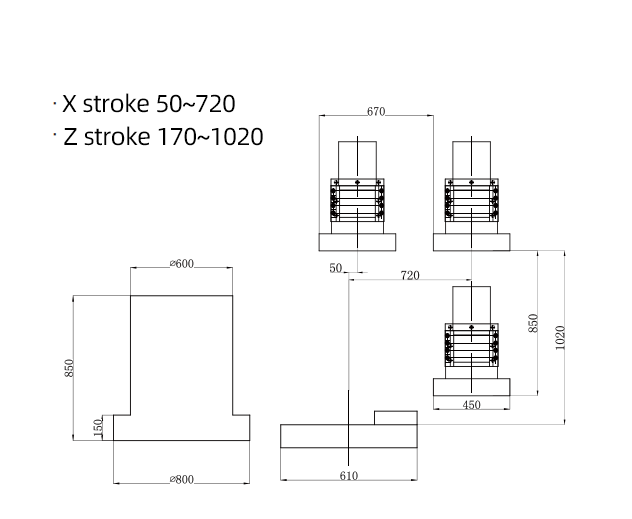

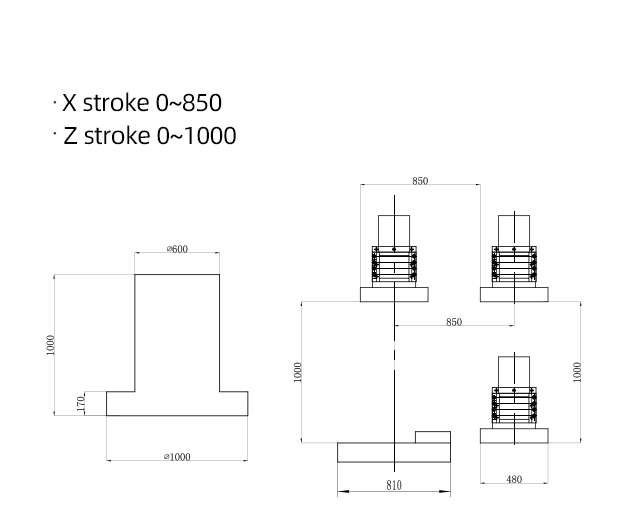

Travel | X axis | mm | 400 | 500 | 425 | 700 | 670 | 850 |

Z axis | mm | 500 | 0~500 | 90~690 | 0~850 | 170~1020 | 0~1000 | |

Machining capability | Max. swing diameter | mm | φ600 | φ650 | φ650 | φ800 | φ1000 | φ1200 |

Max. turning diameter | mm | φ400 | φ500 | φ600 | φ700 | φ800 | φ1000 | |

Max. turning height | mm | 500 | 500 | 600 | 850 | 850 | 1000 | |

Spindle | Spindle speed | rpm | 100-1000 | 100-1000 | 100-1000 | 100-800 | 100-800 | 100-800 |

Spindle motor power | Kw | 15 | 15 | 18.5 | 22 | 22 | 22 | |

Arbor outer diameter | mm | φ130 | φ130 | φ160 | φ160 | φ180 | φ200 | |

Hydraulic chuck + tool holder | Chuck types |

| Hydraulic chuck | |||||

Calibre | inch | 12 | 15 | 18 | 21 | 24 | 32 | |

Turret station |

| 8-station | 4-station/8-station | 4-station/8-station | 4-station/8-station | 4-station/8-station | 4-station/8-station | |

Guideway | X-axis rolling linear guideways |

| 2,width 35mm | 2,width 45mm | 2,width 45mm | 2,width 45mm | 2,width 45mm | 2,width 55mm |

Z-axis rolling linear guideways |

| 2,width 45mm | 2,width 45mm | 2,width 55mm | 2,width 55mm | 2,width 55mm | 2,width 55mm | |

Accuracy | Repeatable Positioning Accuracy | mm | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.005 | ±0.005 |

Positioning Accuracy | mm | ±0.006 | ±0.006 | ±0.006 | ±0.006 | ±0.008 | ±0.008 | |

Min. positioning unit | mm | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | |

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com