PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

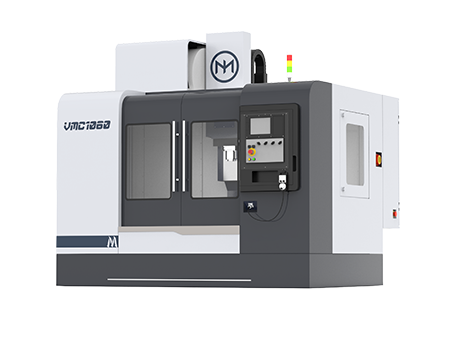

CNC Vertical Machining Centre VMC1160

CNC vertical machining centre VMC1160 adopts X, Y, Z axis servo control semi-closed loop, compact and reasonable structure, large overall size, spindle driven by servo motors, which can be used for small and medium-sized parts of high-efficiency machining and manufacturing, and can achieve the high precision of the parts demanded.VMC1160 machining centre can be formed into an automated production line for large-scale production, in order to ensure the quality of the product and the components of the high efficiency production. High efficiency production.

- Table size: 1200x600mm

- Table maximum load: 1000kg

- X/Y/Z axis travel: 1100x600x600mm

Features

The VMC1160 CNC vertical machining centre, while maintaining the advantages of the traditional vertical CNC milling machine such as high rigidity of the base frame, symmetrical structure and good stability, incorporates the international advanced concept of dynamic rigidity design and carefully optimises the moving parts to enhance the overall performance.

- X, Y, Z-axis servo motor through the flexible coupling and Taiwan high-precision ball screws directly connected to reduce intermediate links, to achieve gapless transmission, flexible feeding, positioning accuracy, high transmission precision.

- The spindle can be stepless variable speed within its speed range. The spindle is controlled by the motor’s built-in encoder, which enables spindle orientation and rigid tapping functions.

- The guide rail and ball screw sub are equipped with centralised automatic lubrication, and each node is equipped with a quantitative oil distributor, which injects oil into each lubrication part at regular intervals to ensure uniform lubrication of the sliding surfaces, which effectively reduces friction resistance, improves motion accuracy and ensures the service life of the ball screw sub and the guide rail.

Applications

- VMC1160 is mostly used for processing plates, discs, shells, moulds and other high-precision, multi-process, complex shape of the parts, can be completed in a single clamping milling, drilling, expanding, hinging, boring, tapping, and two-dimensional three-dimensional surfaces, bevelled surface of the precise machining, machining to achieve the programmed to shorten the production cycle, so that the user to obtain a good economic benefits.

- It is suitable for the processing of automotive parts, electrical instruments, motorbikes, tools, hardware, motors and other industries.

Specifications | Unit | VMC1160 |

Table size | mm | 1200×600 |

Table maximum load | kg | 1000 |

X/Y/Z axis travel | mm | 1100×600×600 |

Distance between spindle center and column | mm | 650 |

Distance between spindle end face and worktable surface | mm | 120-720 |

X/Y/Z Max.feed speed | mm/min | 10000 |

X/Y/Z Max. Rapid traverse | m/min | 32/32/30 |

spindle speed | r/min | 8000 |

spindle taper | type | BT40 |

Spindle motor power | kW | 11/15 |

X/Y/Z axis servo motor power | kW | 4/4/5 |

X/Y/Z motor connection |

| Direct |

X/Y/Z Guide way type |

| Linear |

T slot | mm | 5-18×100 |

Repeat positioning accuracy | mm | ±0.005 |

Tool magazine |

| Disc style |

Tool capacity |

| 24T |

Maximum tool weigh | kg | 8 |

Max. tool length | mm | 300 |

Electric capacity | KVA | 18 |

Machine dimension(LxWxH) | mm | 3100×2490×2380 |

Net. weight (about) | kg | 7000 |

Standard accessories:

- The back row chip full cover sheet metal without the chip.

- Drawer type water tank and chip box.

- Backward impact chip washing device.

- Full-function operation panel and hand wheel.

- ATC.

- Belt drive spindle.

- Sprinkler cooling system at the spindle side.

- Air cooling system at spindle side.

- Heat exchange device of electric cabinet.

- Work area cleaning water gun, air gun.

- Working light and alarm light.

Optional accessories:

- Front row chip full cover sheet metal belt chip remover.

- Central outlet function of spindle.

- 3 axis linear scale.

- Function of the fourth axis.

- Spindle oil cooling function.

- Straight connection drive spindle.

- Oil-water separation device.

- Workpiece and tool measuring device.

- Door open switch.

- High speed and high precision functions.

- Column elevation (bridge type or height block).

For customized needs in the selection and use of accessories for the CNC vertical machining center VMC1160, contact us to learn more.

Related Products

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com