PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

High Torque Gear Spindle Vertical Machining Center MDV55/MDV75/MDV95Series

Vertical Machining Center MDV series is a high precision, high rigidity vertical machining center, which can achieve low speed and high torque operation, and is very suitable for efficient machining of difficult materials such as high-strength steel, high temperature alloys, and steel parts. It is suitable for machining complex mold contours, automotive parts, and service industry box-type parts, and is especially good at mold machining, making it the first choice for small and medium sized mold parts manufacturing.

- Max.swing diameter over machine bed : 1250/1600/2000/2500/3000mm

- Max.swing diameter over cutting tool carriage: 800/1250/1600/2000/2500mm

- Max.work-piece weight: 2/3T

- Max.work-piece length: 500/750mm

Specification | Unit | MDV55 | MDV75 | MDV95 | ||

Worktable | Table size(L*W) | mm | 1050×560(Opt:1250×560) | 1550×740 | 2300×950 | |

Max. load | kg | 800 | 1500 | 2500 | ||

T-slots (numbers*width* centre distance) | mm | 5×18×110 | 5×22×140 | 7×22×125 | ||

Travel | X/Y/Z Axis travel | mm | 1020/550/510 | 1530/740/660 | 2060/950/850 | |

X/Y/Z Axis guide way type |

| Box way | Box way | Box way | ||

Distance from spindle center to column | mm | 615 | 810 | 1100 | ||

Distance from spindle nose to table | mm | 150~ 660 | 150~810 | 150~ 1000 | ||

Feedrate | Rapid traverse of X/Y/Z axis | m/min | 30/30/20 | 24/24/20 | 20/20/15 | |

Max. Cutting feed rate | m/min | 10 | 10 | 10 | ||

Spindle | Spindle motor power | kW | 7.5/11(Opt:11/15) | 7.5/11(Opt:11/15) | 11/15 | Opt: |

Max. spindle speed | r/min | 8000(Gear box)Opt:6000(Gear box) | 6000(Gear box)Opt:8000(Gearbox) | 6000(Gear box) | Opt:4500(Gear box) | |

Spindle taper |

| No.50(7/24) | No.50(7/24) | No.50(7/24) | ||

ATC | Tool magazine capacity |

| 20T(Opt:30T)original high-speed synchronous tool changer | 20T(Opt:30T)original high-speed synchronous tool changer | 30T | |

Tool shank type |

| BT50 | BT50 | BT50 | ||

Max. tool weight | kg | 20 | 20 | 20 | ||

Max. tool diameter(w/o adjacent tools) | mm | 20T:φ110/φ200 | 20T:φ110/φ200 | 30T:φ103/φ200 | ||

Tool change time (T-T) | S | 2 | 2 | 2 | ||

Accuracy | X/Y/Z axis positioning accuracy | mm | 0.008/0.008/0.008 | 0.012/0.008/0.008 | 0.015/0.012/0.012 | |

X/Y/Z axis repeatability accuracy | mm | 0.005/0.005/0.005 | 0.007/0.007/0.007 | 0.007/0.007/0.007 | ||

CNC controller |

| FANUC 31i-B | FANUC 31i-B | FANUC 31i-B | ||

General | Machine dimensions(L*W*H) | mm | 3398×2880×2846 | 4140×4000×3436 | 5458×5380×3600 | |

Machine weight | kg | 7500 | 10500 | 20500 | ||

Features

Electric servo bending machine realizes fast response and precise control through electric servo system, which improves productivity, reduces energy consumption, and lowers noise pollution. Its high-precision positioning capability ensures machining quality while reducing maintenance costs and enhancing the safety of the working environment.

- The X, Y, and Z axis ball screws of the machine tool all adopt advanced hollow cooling technology, effectively controlling thermal deformation during the machining motion and enhancing machining precision. Additionally, the machine tool has a temperature compensation function, with temperature sensors installed at key locations on the machine body. These sensors analyze and compensate for coordinate positions through the CNC system, achieving high precision machining.

- The machine tool spindle employs a variable-speed gear transmission structure with a maximum speed of 8000rpm and two-speed gear shifting, meeting both low-speed cutting requirements and high-speed machining needs. An optional 13000rpm electric spindle is also available. The X, Y, and Z axis guides use high-rigidity imported resin-bonded plastic sheet hardened guide slide pairs. The machine tool’s tool changer employs a robotic arm that releases and retrieves tools via cam linkage, achieving rapid tool changes (2-second tool change time). All these parameters are at the leading domestic and international levels.

- The main body of the machine tool is made entirely of high-strength resin sand castings, with the bed being a integral casting. The column is fixed to the rear bed, while the cross slide and worktable move on it, enhancing the overall stability of the machine tool. Additionally, the machine tool’s structure is optimized through finite element analysis during the design process, making it more rational.

- Original high-speed synchronous tool changer

- Double spiral rear exit chip removal

Applications

- High torque gear spindle vertical machining MDV series is suitable for high efficient machining of difficult to machine materials such as high strength steel, high temperature alloys and steel parts.

- It is widely used for machining complex mold contours, automotive parts, and box parts in the service industry.

Standard accessories:

- Integral shroud

- Original high-speed synchronous tool changer

- Internal two-speed variable high-speed gear spindle + spindle oil cooling device

- Hollow cooling screw

- Double (three for MDV95) spiral rear exit chip removal device

- Automatic lubrication system

- Automatic lubrication system

- Electrical cabinet heat exchanger

- Warning light

- Workpiece cooling system

- Rigid tapping

Optional accessories:

- 30 simultaneous rotary tool magazine (standard configuration for MDV95)

- Center water spindle and high pressure cooling device

- High flow rate chip flushing device

- Electrical cabinet air conditioning

- Fourth axis CNC rotary table

- Column heightening (MDV55, MDV75 only)

- Tool inspection device

- M30 automatic power-off device

- Off-machine lifting chip conveyor

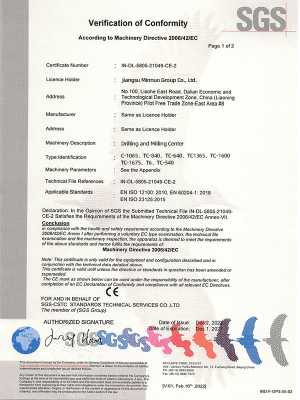

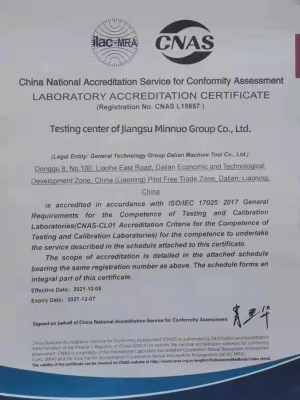

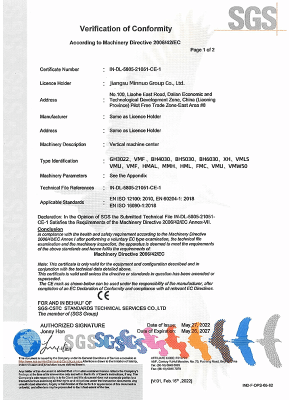

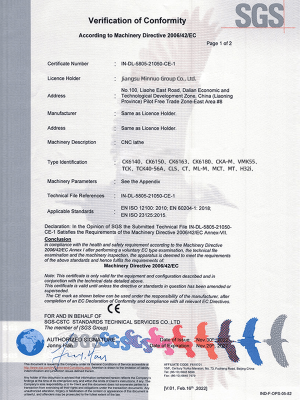

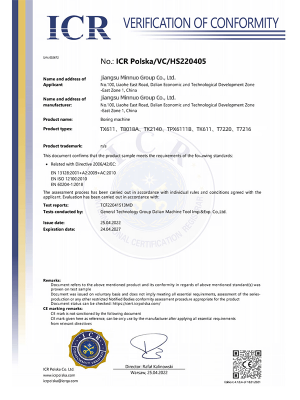

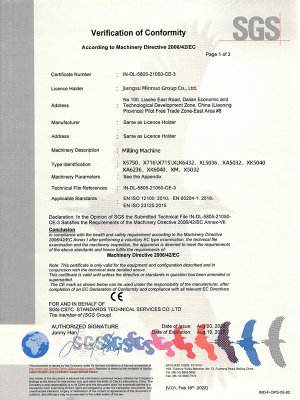

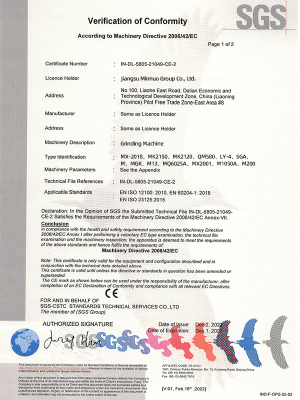

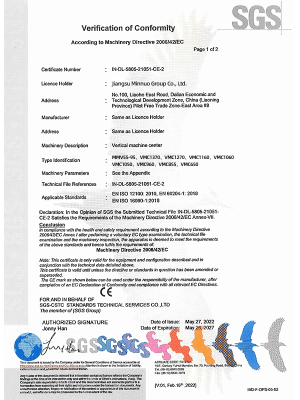

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com