PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

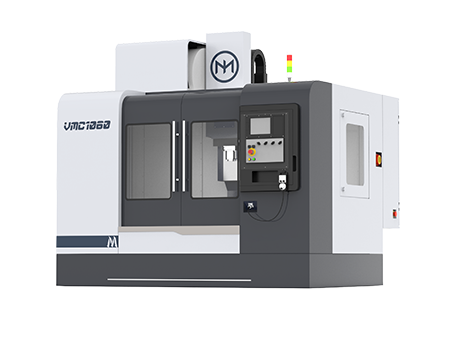

Vertical Machining Center VMD1580

The VMD1580 machining centre is a two lines and one hard machining centre, with linear guideways for the X and Y axes and a rigid hard guideway for the Z axis. The configuration of two lines and one hard has the rigidity of the hard guideway as well as the fast movement and high accuracy of the linear guideway, which makes the machining capability more comprehensive.

- Table size: 1700x800mm

- Table maximum load: 1500kg

- X/Y/Z axis travel: 1500x800x700mm

Specifications | Unit | VMD1580 |

Table size | mm | 1700×800 |

Table maximum load | kg | 1500 |

X/Y/Z axis travel | mm | 1500x800x700 |

Distance between spindle center and column | mm | 871 |

Distance between spindle end face and worktable surface | mm | 150-900 |

X/Y/Z Max.feed speed | mm/min | 10000 |

X/Y/Z Max. Rapid traverse | m/min | 20/20/16 |

spindle speed | r/min | 6000 |

spindle taper | type | BT50 |

Spindle motor power | kW | 15/18 |

X/Y/Z axis servo motor power | kW | 4.5/4.5/4.5 |

X/Y/Z motor connection | Direct | |

X/Y/Z Guide way type | Two wire one hard | |

T slot | mm | 5-22×145 |

Repeat positioning accuracy | mm | ±0.005 |

Tool magazine | disc style | |

Tool capacity | 24T | |

Maximum tool weigh | kg | 15 |

Max. tool length | mm | 300 |

Electric capacity | KVA | 30 |

Machine dimension(LxWxH) | mm | 4260×3545×3200 |

Net. weight (about) | kg | 12000 |

Features

- VMD1580 machine is designed with high speed as the basic starting point, providing guarantee for mass production of parts, precision machining and maximising machining efficiency;

- High-efficiency chip removal, fast feed and spindle high-speed function combination modular, to meet different customer;

- Individual choice of processing needs;

- The key components affecting the quality of the whole machine are imported high-quality parts of the world’s top brands.

Applications

- The VMD1580 vertical machining centre for the machining and mould making industries is capable of performing a wide range of machining tasks from roughing to finishing, including a variety of processes such as milling, drilling, tapping and boring.

- It is suitable for the processing of moulds and products in hardware mould industry, engraving mould industry automobile industry and so on.

Standard accessories:

- The back row chip full cover sheet metal without the chip.

- Drawer type water tank and chip box.

- Backward impact chip washing device.

- Full-function operation panel and hand wheel.

- ATC.

- Belt drive spindle.

- Sprinkler cooling system at the spindle side.

- Air cooling system at spindle side.

- Heat exchange device of electric cabinet.

- Work area cleaning water gun, air gun.

- Working light and alarm light.

Optional accessories:

- Front row chip full cover sheet metal belt chip remover.

- Central outlet function of spindle.

- 3 axis linear scale.

- Function of the fourth axis.

- Spindle oil cooling function.

- Straight connection drive spindle.

- Oil-water separation device.

- Workpiece and tool measuring device.

- Door open switch.

- High speed and high precision functions.

- Column elevation (bridge type or height block).

For customized needs in the selection and use of accessories for the vertical machining center VMC1580, contact us to learn more.

Related Products

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com