PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

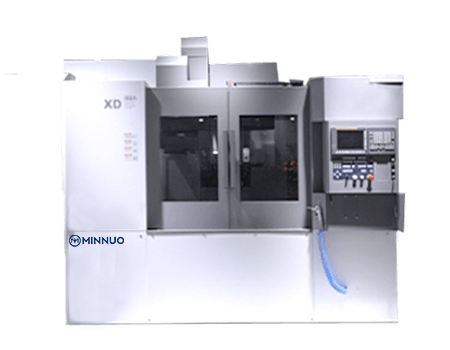

3 Axial Vertical CNC Milling Machine XD Series

3 axis vertical CNC milling XD series is a new generation of CNC machine tools produced by the company’s introduction of advanced technology, the main part mainly consists of base, column, saddle, table, spindle box and other components, of which the main body of the five main parts are high-strength high-quality castings and resin sand modeling, organizational stability, to ensure that the machine has good rigidity and accuracy of the retention of sex. The three-axis guide rails adopt high-frequency quenching and plasticized guide rail combination to ensure the running accuracy of the machine, reduce friction resistance and loss, and the three-axis transmission system consists of precision ball screw and servo system motors, and is equipped with automatic lubrication device.

- Table size: 800*420mm

- Max.load: 500kg

- X/Y/Z axis travel: 620/440/540mm

Specification | Unit | XD-40A |

Table size | mm | 800×420 |

Max. table load | kg | 500 |

Table T-slot (number*width*distance) | mm | 3*18*125 |

Travel (X/Y/Z) | mm | 620/440/540 |

Rapid travel speed (X/Y/Z) | m/min | 24/24/20 |

X, Y, Z Max. cutting speed | m/min | 10 |

Distance from spindle centerline to column front | mm | 550 |

Distance from spindle end face to table plane | mm | 140~680 |

Spindle speed | rpm | 8000 |

Tool shank form |

| BT40 |

Pull-tab |

| BT40-45° |

Gas source pressure | MPa | 0.5~0.8 |

Machine weight | kg | 4000 |

Machine Size | mm | 2413*2451*2549 |

Features

Vertical milling machine XD series unique high-speed linear rolling guideway sub (X, Y, Z axis) design, equipped with automatic lubrication system, cooling system, manual spray gun and portable manually operated device (MPG), with semi-enclosed protective cover.

- Vertical CNC milling machine base, column, spindle box, cross slide, table and other basic parts are all high-strength cast iron, stable organization, to ensure quality. The casting structure has been analyzed by machine dynamics and finite element analysis, and the reasonable degree of structure and the matching of reinforcement ensures the high rigidity of the base parts. Wide and solid machine base, box cavity column, load fully supported cross slide can ensure heavy load capacity during machining.

- High speed precision spindle:

(1) The spindle motor is driven by a high torque toothed belt, which is non-slip and can significantly reduce transmission noise and heat.

(2) The spindle adopts precision grade angular contact bearings, and the standard speed can reach 8000r/min.

(3) High-performance grease lubricated spindle bearings and economical spindle head cooling system effectively control spindle temperature rise.

(4) The spindle utilizes IRD dynamic balance correction equipment to directly correct the dynamic balance of the spindle, so that the spindle avoids resonance phenomenon when running at high speed to ensure machining accuracy.

High precision ball screw sub, ball screw after pre-stretching, greatly increase the transmission rigidity and eliminate the effect of thermal deformation generated by rapid movement, to ensure the positioning accuracy and repeatability of the machine tool positioning accuracy.

The spindle box movement (Z-axis) is equipped with a counterweight device with a central guide design (limited to FANUC-0i-mate, Dalian CNC, HNC CNC, MITSUBISHI-E68 system and GSK983M system), so that the counterweights do not shake even during high-speed movements. The precise ratio of counterweight to spindle housing weight provides optimum machining characteristics. And the Z-axis drive motor has good load characteristics.

Adopting manually operated pneumatic tool changer (BT40 toolholder), the tool changer is fast, stable and reliable.

3-axis vertical milling machine is equipped with semi-closed shield, which is beautiful, safe, leak-proof and protects the environment. Spiral automatic chip removal device (full protection) is simple, environmentally friendly, suitable for general metal and non-metal chip transportation.

Efficient automatic lubrication system: the guide rail lubrication adopts electric pressure-removing lubrication pump, which has good lubrication and does not waste lubricant.

Exquisite oil-water separation equipment reduces the mixing of cutting fluid oil and water, avoids deterioration of cutting fluid and prolongs service life.

Wiring in the electrical box meets the safety standard to ensure that the control system operates without external interference. The electric box is equipped with a heat exchanger to effectively control the temperature inside the electric box to ensure that the control system can operate stably for a long time.

High-precision pitch compensation, each drive shaft is compensated by high-precision laser measuring instrument so that the positioning accuracy of each axis is more accurate, more suitable for processing high-precision parts.

Applications

3 axis vertical CNC milling machine XD series is widely used in small and medium batch processing of box parts, small plates, disks, shells, precision parts and other multi-species parts. The parts can be automatically finished milling, boring, drilling, expanding, reaming, tapping and other multi-process machining after one clamping.

3 axis vertical milling machine unique high-speed linear rolling guideway sub (X, Y, Z axis) design, the machine tool is widely used in the military, aerospace, automotive, mold, machinery manufacturing and other industries, box parts, shell parts, disk-shaped parts processing.

| Accessories | XD-40A |

| Semi-closed shield | ● |

| Integral protective cover | ○ |

| Automatic lubrication system | ● |

| High speed spindle (10000rpm) | ○ |

| Spindle oil cooling | ○ |

| Spindle air seal | ● |

| BT40-45° pull-tab | ○ |

| Rigid tapping | ● |

| Workpiece Cooling Unit | ● |

| Tools and toolboxes | ● |

| RS-232 transmission systems | ● |

| Electrical cabinets and heat exchange systems | ● |

| Floor bolts and pads | ● |

| Machine lights | ● |

| Warning Lights | ● |

| Manual chip conveyor | ● |

| Screw chip conveyor | ○ |

| Fourth axis CNC rotary table | ○ |

| Bucket type tool changer | ○ |

| Robotic tool changer | ○ |

| Hand-held chip blowing air gun | ○ |

| Electric spare parts | ○ |

| Automatic tool inspection device | ○ |

| Automatic workpiece inspection system | ○ |

| M30 Automatic power-off system | ● |

| Electric cabinet thermostat control unit (air conditioner) | ○ |

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com