PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

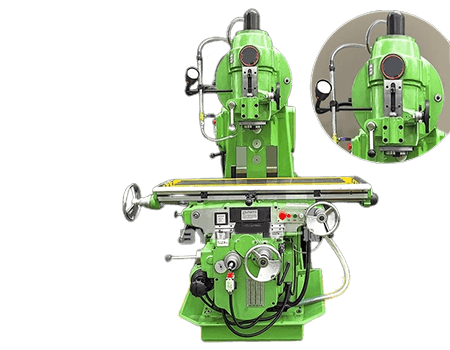

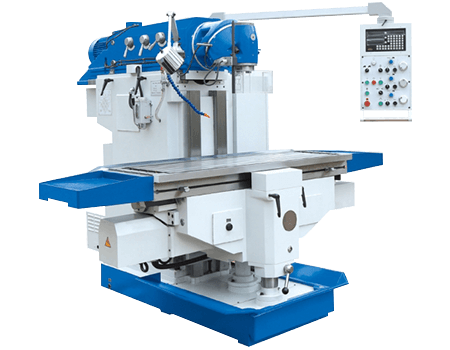

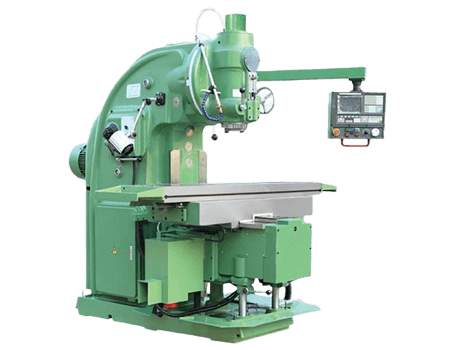

CNC Vertical Lift Table Milling Machine xk5040 Series

CNC vertical lifting table milling machine is an improved universal product. The product is easy to operate, reliable performance, widely used in various types of machining departments, processing a variety of flat surfaces, grooves, gears, etc. Configuration of universal milling head, round table, indexing head, digital display and other milling machine attachments, can further expand the scope of use of the milling machine.

- Table size: 1700*400mm

- Longitudinal travel: 1000mm

- Cross travel: 350mm

Specification | Units | XK5040 | XK5032 |

Table size | mm | 1700*400 | 1600*320 |

T slots (N/W/D) | mm | 3/18/90 | 3/18/70 |

Longitudinal travel | mm | 1000 | 900 |

Cross travel | mm | 350 | 310 |

Vertical travel | mm | 375 | 350 |

Table longitudinal feed ( auto) | mm/min | 6-3200 | |

Table cross feed ( auto) | mm/min | 6-3200 | |

Table vertical feed ( auto) | mm/min | 3-1600 | |

Distance between spindle and table surface | mm | 90-465 | 35-385 |

Spindle hole taper |

| ISO 50(7:24) | |

Spindle speed step | step | 18 | |

Spindle speed range | r/min | 30-1500 | |

Max. swivel an gle of head |

| ±45° | |

Stroke of spindle quill | mm | 85 | 70 |

Power of spindle motor | kw | 11 | 7.5 |

Torque of X/Y/Z axis AC servo motor | N. m | 15/15/23 | 10/10/18 |

Overall size | mm | 2760*2160*2250 | 2040*1800*1910 |

Net weight | kg | 4200 | 2900 |

Features

Vertical lifting milling machine adopts CNC rotary table, which can be used both vertically and horizontally. For bar machining, the rotary table is fixed vertically on the working table, and fixed on the indexing head by chuck and tailstock clamping to realize the function of automatic indexing at various angles of 360°. This kind of clamping method, the setting unit is 0.001°, supports four-axis and four-link function.

- CNC System: The bus system adopts SIEMENS808D, optional with Fanuc OIMF system, Siemens system, Mitsubishi M80 system, wide number of systems, in line with the human body engineering type interactive interface, can complete the requirements of high-precision milling processing, friendly humanized interactive experience.

- Castings: Vertical lifting milling machine base, bed, lifting platform, table, head box are made of high-grade HT250 material casting, by the second tempering treatment, the natural aging treatment, so that the casting to release the internal stresses, greatly improving the casting of the precision of the casting to maintain the amount of deformation of the casting is effectively passed down.

- Scraping process: the combined surface of the machine tool have gone through manual scraping process, the precision of the machine tool is good, the accuracy is maintained better, the scraping surface retains lubricating oil, to ensure that the guide rail lubrication and durability.

- Milling head: spindle noise is in line with international standards, strictly controlled within 80 dB, vertical milling head can be rotated positively or negatively by 45° in the vertical plane.

- Servo motor: 3-axis servo motor adopts servo motor drive, which can realize infinite speed regulation of feeding, good stability, fast response speed, and double the working efficiency.

- Gears and oil pumps: Carburized gears with low noise, high precision, and extended service life with RH carburizing technology; electronic oil injection pump, timed quantitative forced lubrication system, with loss of pressure and oil shortage safety protection and alarm.

Applications

- Vertical CNC lifting table milling machine XK5040 series, the guide surface paste plastic process, combined with the surface are after manual shovel scraping process, suitable for processing a variety of parts of the plane, inclined plane, groove, hole, etc., is the machinery manufacturing, molds, instruments, instruments, automobiles, motorcycles and other industries, the ideal machining equipment

Structure Diagram

Configure

Standard accessories: SIEMENS808D

Optional accessories:

The fourth axis CNC rotary table

CNC dividing head

CNC system: FANUC、Mitsubishi、GSK980MDC

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com