PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

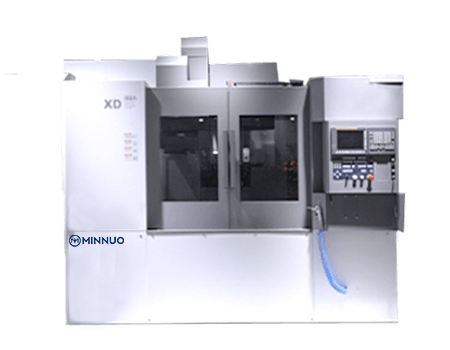

+Machining centers

+Lathe Machine

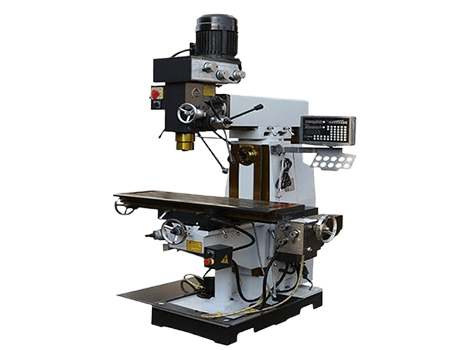

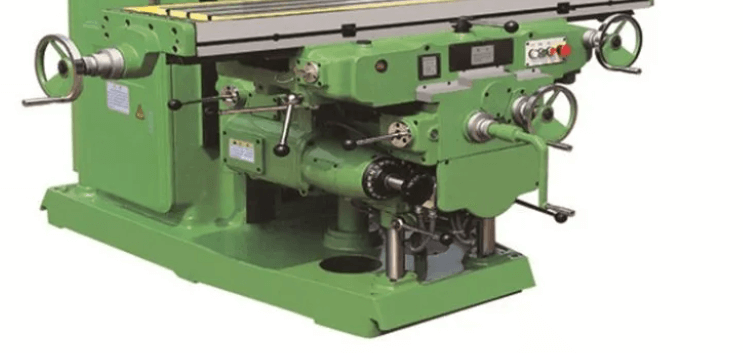

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

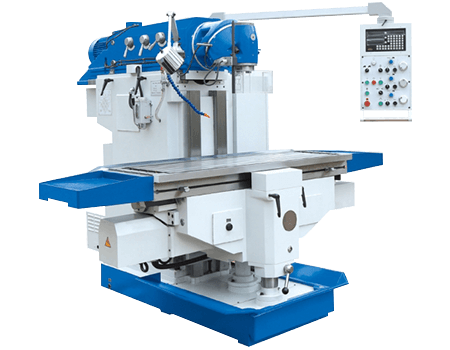

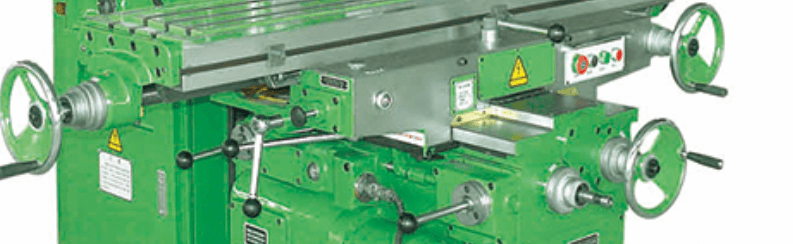

Conventional Vertical Milling Machine X5032 Series

Conventional vertical milling machine spindle vertical arrangement, in addition to the spindle arrangement is different, the table can be lifted up and down, vertical milling machine with milling cutter is relatively flexible, the scope of application is wider. Can use vertical milling cutter, machine-clamped cutter disk, drills and so on. Keyway milling, milling plane, boring and so on. Productivity is higher than horizontal milling machines.

- Table size: 320X1600mm

- Longitudinal travel(manual/auto): 900/880mm

- Cross travel(manual/auto): 255/240

- Vertical travel(manual/auto): 460/440

Specification | Unit | X5032 | X5032B | X5032H | X5032BH |

Table size | mm | 320X1325 | 320X1600 | 320X1325 | 320X1600 |

T-slots ( NO./Width/Pitch) |

| 3/18/70 | |||

Longitudinal travel(manual/auto) | mm | 700/680 | 900/880 | 700/680 | 900/880 |

Cross travel(manual/auto) | mm | 255/240 | |||

Vertical travel(manual/auto) | mm | 370/350 | 460/440 | ||

Rapid feed speed X/Y/Z | mm/min | 2300/1540/770 | |||

Spindle bore diameter | mm | 29 | |||

Spindle taper |

| 7:24 ISO50 | |||

Spindle speed range | r/min | 30-1500 | |||

Spindle speed step | steps | 18steps | |||

Stroke of spindle quill | mm | 70 | |||

Max. swivel angle of vertical milling head |

| ±45° | |||

Distance between spindle nose and table surface | mm | 30-400 | 30-490 | ||

Distance between spindle axis and column guideway | mm | 350 | |||

Feed motor power | kw | 1.5 | |||

Main motor Power | kw | 7.5 | |||

Overall size(L×W×H) | mm | 2294×1770×1904 | 2294×2050×1904 | 2294×1770×2084 | 2294×2050×2084 |

Net weight/Gross weight | kg | 2900/3200 | 3000/3300 | 3100/3400 | |

Features

- Conventional vertical milling head:

1.The milling head can be adjusted 45° in the vertical plane for forward and reverse rotation;

2.The spindle sleeve can be micro-fed manually and is equipped with a limit device;

3.The spindle bearing adopts tapered roller bearing with high load capacity, and it adopts energy consumption brake with high braking torque, stopping quickly and reliably.

- Worktable:

1.It can be manually fed and lifted vertically in longitudinal and transverse directions, and at the same time, it can realize motorized fast forward, motorized feeding and vertically motorized lifting and lowering in longitudinal and transverse directions;

2.Table X, Y, Z three-direction guideway vice by ultra-audio quenching, precision grinding and scraping treatment, with mandatory lubrication, improve precision and extend the service life of the machine tool.

- Lubrication device:

1.Adopt forced lubrication;

2.Forced lubrication of X, Y, Z direction screws and guide rails reduces the wear and tear of the machine and ensures the efficient operation of the machine tool;

3.The cooling system changes the size of the coolant flow by adjusting the nozzle to

4.To meet different machining requirements.

- Work feeding:

1.The worktable 3-way has three modes of manual feeding, motorized feeding and motorized rapid feeding, which can meet different processing requirements; the rapid feeding mode can make the workpiece reach the processing position quickly, shorten the non-processing time and improve the working efficiency.

2.Conventional vertical milling machine easy to wear castings using vanadium and titanium wear-resistant cast iron, important parts of high-quality alloy steel, stable and durable. And by artificial aging treatment, to ensure the stability of the machine tool for long-term use.

3.The spindle motor has high power and wide range of variable speed, giving full play to tool efficiency and high-speed cutting. The machine tool is designed in accordance with the principle of ergonomics and is easy to operate; the operation panels are all designed with visualized symbols, which are simple and intuitive.

Applications

- Conventional vertical lifting table milling machine is mainly used in more than 20 industries such as mold processing, teaching equipment, automobile parts, coal machine and mining machine, engineering machinery, wind power production, rail transportation, electronic machinery, aerospace, papermaking and printing and dyeing.

- Optional universal milling head, round table, indexing head and other milling machine accessories to expand the scope of addition.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com