PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

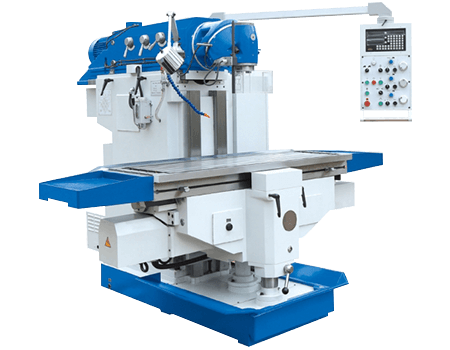

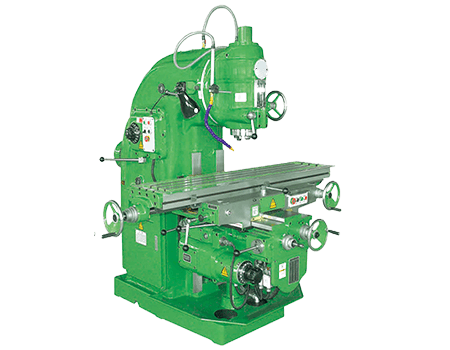

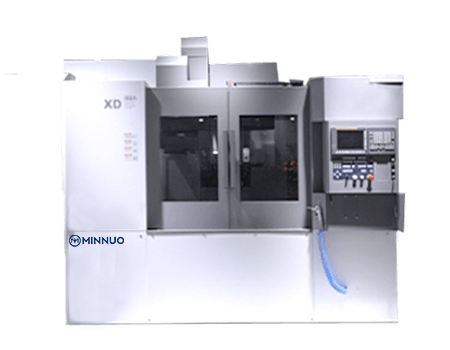

Drilling & Milling Machine Series

Drilling and milling machine is a collection of drilling, milling, boring, grinding in one machine tool equipment, applied to small and medium-sized parts processing. The worktable can be moved vertically and horizontally, the spindle is arranged vertically, usually desktop, the head can be lifted up and down, with drilling, milling, boring, grinding, tapping and other cutting functions of the machine tool. The spindle box can rotate left and right by 90° in the vertical plane, and the table of some models can rotate left and right by 45° in the horizontal plane, and the table of most models can be longitudinally automatic tool walking.

- Table size: 1000×240mm

- Max width of end milling: 100mm

- Max diameter of bore hole: 50mm

Specifications | Unit | ZX7550CW |

Max diameter of bore hole | mm | 50 |

Max width of end milling | mm | 100 |

Max diameter of vertical milling | mm | 25 |

Max diameter of boring | mm | 120 |

Max tapping diameter | mm | M16 |

Distance from spindle end to worktable | mm | 90-490 |

Spindle speed range | rpm | (V)115-1750/(H)80-1300 |

Spindle stroke | mm | 120 |

Worktable size | mm | 1000×240 |

Table travel | mm | 500×230 |

Outer size | mm | 1280×1100×2080 |

Motor power | kw | 2.2(V)/1.5(H) |

Weight | kg | 1000/1100 |

Features

The drilling and milling machine has advanced and reasonable structure, light and flexible operation, easy maintenance, and can generally meet the requirements of IT8 level accuracy and roughness.

- Drilling and milling machine table can move longitudinally and transversally, the spindle is arranged vertically, usually desktop, the head can be lifted up and down, the spindle box and the table can be lifted and lowered, can also be rotated around the column, expanding the processing range;

- With drilling, milling, boring, grinding, tapping and other cutting functions. The spindle box can rotate 90° left and right in the vertical plane, and the table of some models can rotate 45° left and right in the horizontal plane, and the table of most models can be longitudinally automatic tool walking;

- The drilling and milling machine has 12 levels of variable speed and a wide range of speeds, which is suitable for machining all kinds of commonly used soft and hard materials;

- The machine tool can realize both vertical and horizontal milling functions; the vertical spindle sleeve has both manual and micro-feeding.

Applications

- Drilling and milling machine is a small and medium-sized general-purpose metal cutting machine tool, namely, horizontal milling and vertical milling. It is suitable for drilling, expanding, reaming, boring, hole processing; such as with circular piece milling machine, angle milling cutter, forming milling cutter and end milling cutter, can milling plane, inclined plane, vertical plane and groove, etc..

- Widely used in single piece or batches of machinery manufacturing, instrumentation industry, building decoration and repair departments.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com