PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

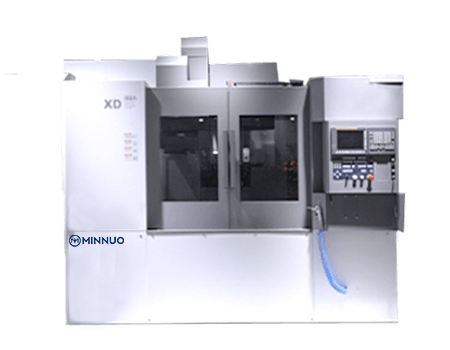

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

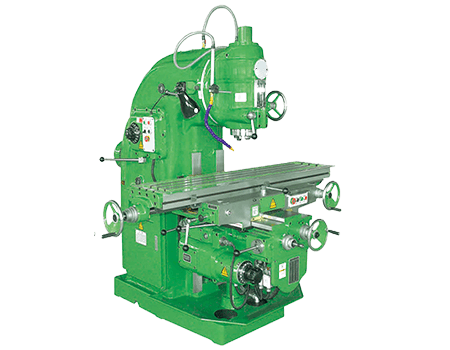

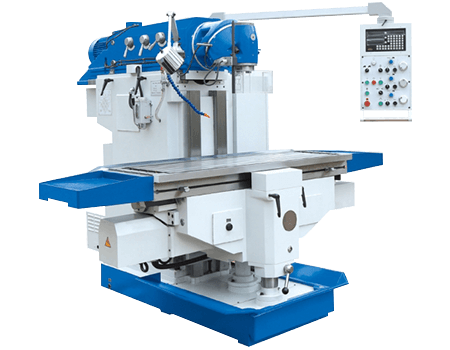

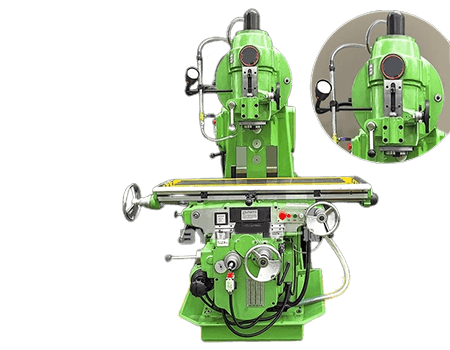

Heavy Duty Vertical Milling Machine XA5032 Series

Heavy-duty vertical lift milling machine XA5032 is an improved X5032 type, which can be used for the processing of heavy parts. The milling machine is easy to operate, reliable performance, widely used in all kinds of machining departments, processing a variety of flat surfaces, grooves, gears, etc. Configuration of universal milling head, round table, indexing head, digital display and other milling machine accessories, can further expand the scope of use of the milling machine.

- Table size: 320*1325mm

- Max. load of table: 500kg

- Distance of T-slot: 70mm

| Specifications | Units | XA5032 |

| Table size (length×width) | mm | 320*1325*1700 |

| Max. load of table | kg | 500 |

| Number of T-slot | 3 | |

| Width of T-slot | mm | 18 |

| Distance of T-slot | mm | 70 |

| Longitudinal travel(manual/auto) | mm | 700/680, 1100/1080 |

| Transverse travel(manual/auto) | mm | 255/240 |

| Vertical travel(manual/auto) | mm | 370/350 |

| Taper hole | 7:24(ISO No.50) | |

| Spindle speed range | rpm | 30-1500 |

| Spindle speed step | steps | 18 |

| Spindle motor power | kW | 7.5 |

| Feed motor power | kW | 2.2 |

| Dimension | mm | 2800 |

| Machine weight | kg | 2295*1770*2094 |

Features

- The end milling head can be adjusted ±45 in the vertical plane, expanding the machining range of the machine.

- Spindle bearings are tapered roller bearings with strong load capacity, and the spindle adopts energy consumption brake with large braking torque, stopping quickly and reliably.

- The table is made of high-strength material casting, and by artificial aging treatment, to ensure the stability of the machine tool for long-term use of the table X / Y / Z direction of the table has a manual feed, motorized feed and motorized fast feed three kinds of feed speed to meet the different processing requirements: fast feed can make the workpiece quickly to reach the machining position, processing is convenient, fast, shorten the non-processing time lubrication device.

- The lubrication device can lubricate the longitudinal, transverse and vertical screws and guide rails forcibly to reduce the wear and tear of the machine tool and ensure the efficient operation of the machine tool: at the same time, the cooling system can change the size of the coolant flow by adjusting the nozzles to meet the different machining requirements.

Applications

Heavy-duty vertical conventional milling machines are widely used in machinery manufacturing, automotive, aerospace, energy, mold making, heavy machinery, construction, railroad, shipbuilding and military industries, etc. With its high rigidity, high precision and heavy-duty cutting capacity, it meets the high quality and high efficiency requirements of large workpiece machining.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com