PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

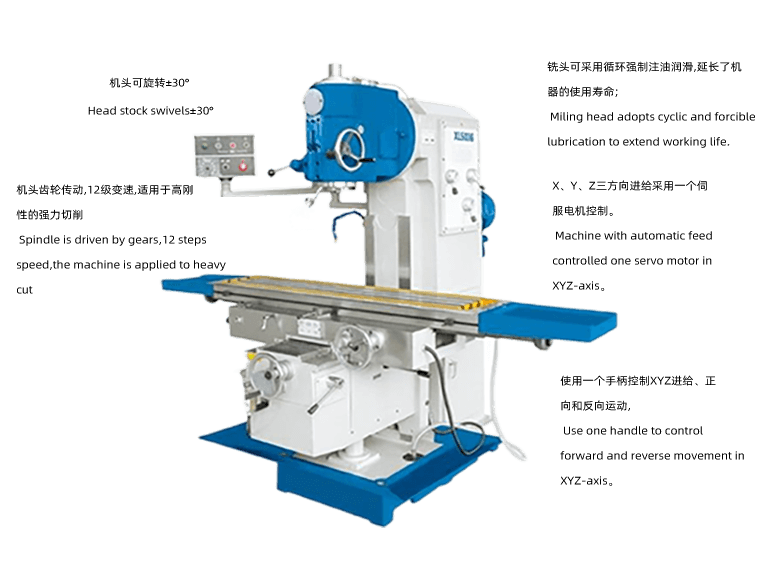

Servo Structure Small Economy Vertical Milling Machine XL5036 Series

Compact economic vertical milling machine is driven by servo motor, equipped with 1600*320mm table and 300kg load capacity.X/Y/Z axis guideway is wear-resistant and hand-scraped to ensure the accuracy.HT250 castings are tempered and aging-treated to enhance the durability. The main drive and feed drive system provide multi-speed adjustment and convenient electrical control, which is suitable for machining large workpieces.

- Table size: 1600*320mm

- Table load: 300kg

- T-slot number/width/distance: 3/18/70

| Specifications | Unit | XL5032 | XL5032C | XL5032CL |

| X-travel manual/motorized | mm | 750 | 1100 | 1300 |

| Y-stroke manual/motorized | mm | 320 | 320 | 320 |

| Z-stroke manual/motorized | mm | 450 | 450 | 450 |

| Spindle taper | mm | ISO50(7:24) | ISO50(7:24) | ISO50(7:24) |

| Spindle power | KW | 5.5 | 5.5 | 5.5 |

| Spindle bore diameter | mm | 29 | 29 | 29 |

| Spindle speed/step | rpm | 50-1475/12 | 50-1475/12 | 50-1475/12 |

| Spindle sleeve stroke | mm | 70 | 70 | 70 |

| Head swivel angle | mm | ±30° | ±30° | ±30° |

| Table size | mm | 1325×320 | 1325×320 | 1600×320 |

| Table load | kg | 300 | 300 | 300 |

| X, Y, Z feed speed | Mm/min | 30-750/20-500/15-375 | 30-750/20-500/15-375 | 30-750/20-500/15-375 |

| X,Y,Z rapid traverse speed | M/min | 1200/800/600 | 1200/800/600 | 1200/800/600 |

| T-slot number/slot width/slot distance | mm | 3/18/70 | 3/18/70 | 3/18/70 |

| Distance from spindle end face to table surface | mm | 30-490 | 30-490 | 30-490 |

| Distance from spindle centerline to column guideway | mm | 378 | 378 | 378 |

| Feed motor power | N | 10 | 10 | 10 |

| Dimensions | mm | 1800x2100x2150 | 2245x2100x2150 | 2520x2100x2150 |

| Weight | Kg | 2750 | 2850 | 2900 |

Features

- Machine tool guideway: X/Y/Z-axis guideway after ultra-frequency quenching treatment, high wear resistance; contact surface manual scraping, high precision.

- Scraping and research process: all machine tool bonding surface are manually shove

- Castings: base, bed, lifting platform, table, head box are made of high-grade HT250 casting materials, by the second tempering treatment, natural aging treatment, so that the castings to fully release the internal stress, greatly improving the casting precision retention, a greater limit of passing down the amount of casting deformation.

- Working table: large area 1600x320mm, can bear 300Kg weight, suitable for large workpiece processing, X square stroke 1300mm, processing length long.

- Basic structure

- Machine body: consists of base and bed, the bed is fixed on the base.

- Lifting platform: cooperates with the dovetail guideway of the bed, lifting and lowering vertically along the guideway of the bed.

ransmission system

- TMain transmission: installed in the bed, through the bed on the right side of the cover plate of the three variable speed handle to adjust the spindle speed.

- Feed drive: installed in the lifting table, the AC servo motor outputs different rotational speeds, and the power is transmitted to the longitudinal, transverse and lifting screws respectively through gear transmission.

- Moving parts

- Working table: driven by the screw and screw mother to move longitudinally and transversally.

- Slide base: the lifting table and slide base are matched by rectangular guide rail, and the working table and slide base are matched by dovetail guide rail.

- Cooling and Lubrication

- Cooling: Coolant is stored in the inner cavity of the base.

- Lubrication: the main drive part is forced lubrication by lubricating oil pump, the feeding drive part is oil-immersed splash lubrication, and the rest of the moving parts are fixed-point lubrication by hand-pulled oil pump or oil cup.

- Electrical control

- Electrical box: hidden in the bed.

- Control operation: respectively mounted on the left side of the lifting platform, the right side of the bed or supported by the cantilever bracket in front of the left side of the machine tool, easy to operate.

Applications

CNC facing lathe, through the automatic control of CNC system (FANUC/SIEMENS/GSK/KND,etc) , can be used for turning various kinds of inner hole, outer circle, conical surface, circular arc surface and thread.

CNC face lathe machine CK64 series have a large load capacity, strong rigidity, beautiful appearance, easy to operate to turn various parts of the internal and external cylindrical surfaces, end faces, arcs and other molding surfaces, is the processing of a variety of tire abrasives and large plane discs, a variety of flanges, pipe fittings, valves, pressure vessels, mining machinery, the ring class of parts of the ideal equipment.

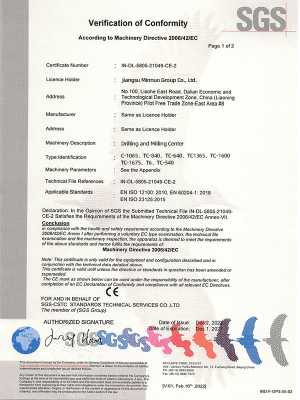

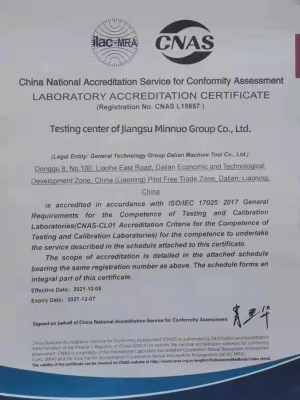

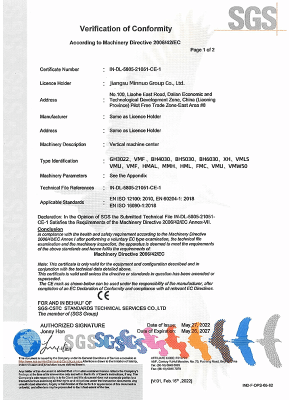

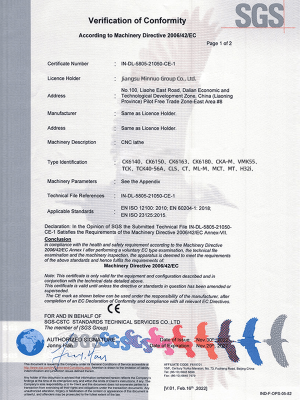

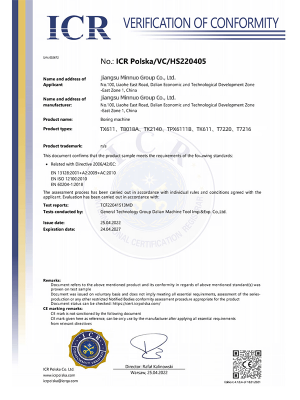

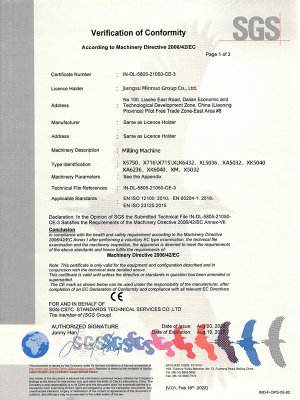

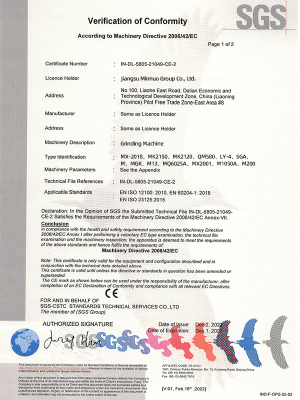

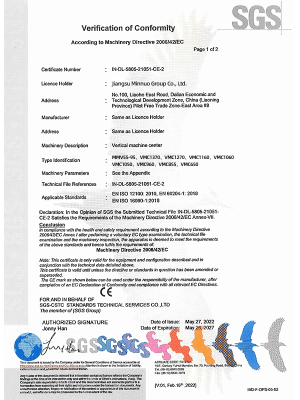

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com