PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

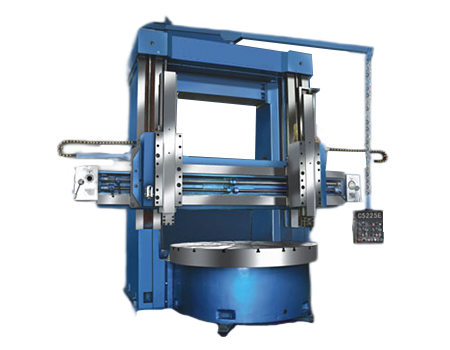

CNC Single Column Vertical Turret Lathe

CNC single column vertical turret lathe adopts the bed structure designed by finite element analysis method, optimizes the main transmission chain, improves the maximum torque output, reduces the force on the gear inside the main gearbox, and adapts to the heavy-duty powerful cutting. It is suitable for machining large workpieces with diameters ranging from 2300 to 2500 mm, and is widely used in heavy industry, energy, shipbuilding and aviation.

- Max.Turning diameter: 2500mm

- Max. height of workpiece: 1250/1600/1800mm

- Max. weight of workpiece: 10T

- Table diameter: 2200mm

Features

- The traditional single-column CNC turret lathe adopts the bed structure redesigned by finite element analysis method to ensure the rigidity during forced cutting.

- Optimize the main transmission chain, improve the maximum torque output, reduce the force of the gears in the main gearbox, adapt to heavy-duty strong cutting.

- The machine has a double-cylinder balanced CNC vertical tool holder.

- Large diameter ball screws, pairs of angular contact screws special bearing support, pre-tensioned structure, imported backlash-free coupling.

- The same spindle structure as the standard CNC vertical lathe, high efficiency, high precision, high bearing, maintenance-free.

- Equipped with electronic handwheel, system-controlled quantitative lubrication pump, electric cabinet air conditioner, full set of Schneider electrical components.

Optional Configurations

- Users can choose their own FANUC/SIEMENS/GSK/HNC system according to the needs of machining parts.

- You can choose the square ram, manual five-station tool holder or electric four/five-station tool holder, BT50 built-in puller mechanism ram.

- The main drive can choose mechanical 16-stage variable speed or AC frequency conversion combined mechanical four-stage variable speed.

- The spindle can choose encoder to realize thread turning function.

Applications

Conventional single column turret lathe series is mainly used for machining complex curved surfaces, irregular shapes, tapers, threads and other parts.

This type of lathe is usually used in a variety of machine building industries, especially when large, heavy and complex shaped parts need to be machined.

Specification | Unit | CJK5123G H/W | CJK5125G H/W |

Max.Turning diameter | mm | 2300 | 2500 |

Table diameter | mm | 2000 | 2200 |

Max. height of workpiece | mm | 1250/1600/1800 | 1250/1600/1800 |

Max. weight of workpiece | t | 10 | 10 |

Max. Cutting force of vertical tool post | kn | 30 | 30 |

Max. Cutting force of side tool post | kn | 20 | 30 |

Total cutting force | kn | 45 | 45 |

Max.torque of table | kn.m | 32 | 50 |

Table speed range | r/min | 3.2-100 | 2-63 |

Swivel angle of vertical tool post | ° | ±30 | ±30 |

CNC vertical tool post feed steps |

| stepless | |

Vertical tool post feed steps | mm/min | 0.1-500 | 0.1-500 |

Max.travel of cross beam | mm | 900/1250/1750 | 900/1250/1750 |

Cross beam lifting speed | mm/min | 440 | 440 |

Max.travel of vertical tool post(horizontal) | mm | 800/1000/1100 | 800/1000/1100 |

Max.travel of vertical tool post(vertical) | mm | 1325 | 1400 |

Vertical tool post rapid traverse speed | mm/min | 3000 | 3000 |

Cross-sectional dimensions of cutterbar (W*H) | mm | 40*40 | 40*40 |

Main motor power | Kw | 37 | 37 |

CNC system |

| FANUC/SIEMENS/GSK/HNC | |

Electronic handwheel |

| TOSOKU | |

Machine dimensions (L*W*H) | cm | 341*405*420 | 370*440*430 |

Net weight | t | 20 | 24 |

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com