PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

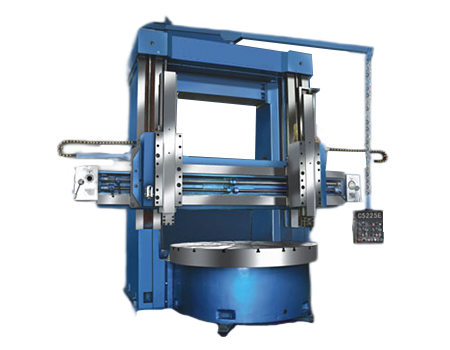

Universal Double Column Turret Lathe CA52/CQ52/C52Series

Universal double column vertical lathe, the main drive of the machine is divided into two kinds of AC and DC, the table is divided into sliding guideway and static guideway for users to choose. 1-25T load table adopts dynamic and static guideway, and 32 tons load table adopts constant-current static guideway. It can be widely used in roughing and finishing machining of electric motor, hydraulic turbine, aviation, mining and other industries, among which the machining height of 3200mm and 3500mm models are widely used in the machining of wind turbine wheel hub.

- Max.Turning diameter: 6000mm

- Max. height of workpiece: 2100/2600/3200/3500mm

- Max. weight of workpiece: 25/40T

- Table diameter: 4500mm

Features

- The main drive logic control is controlled by Japan OMRON programmable control PC with good reliability.

- Increased table base and table diameter, that is, increase the diameter of the table circular guideway, the benefits are:

- Increase the diameter of the large gear ring, so that the main transmission chain of the final stage of the reduction ratio and the total reduction ratio are increased, to obtain 1.25 ~ 40r/min standard 16-step variable speed, without increasing the main motor power in the case of the table’s output torque has been improved, the gear box gear force is reduced, the gear box gearing is greatly reduced.

- Improve the hydraulic system, increase the volume of the oil tank, the continuous operation of the machine is more stable and reliable.

- The cross section of column, beam and coupling beam is enlarged for CA5250 and above models.

① improve the table load capacity, load capacity increased to: 25 tons (dynamic static pressure guideway) / 32 tons (constant flow static pressure guideway).

②Improve the rotary accuracy and smoothness of operation of the table under eccentric load conditions.

③Increase the area of clamping work, which is especially favorable for processing large-size sleeve flange parts.

Optional configuration

- Accessories such as cooling unit, digital display unit, etc.

- Optional thread turning device, can accurately turn large diameter and large lead threads.

- The feeding system can be equipped with the traditional 18-stage mechanical feeding method or with ball screw, high-precision planetary reducer, servo motor drive, with an electronic handwheel for easy tool setting, faster fast moving speed, easy operation and low labor intensity.

Applications

This series of lathe machine can be used for roughing and finishing machining of internal and external cylindrical surfaces, conical surfaces, end surfaces, grooving and so on. It is used in electric motor, hydraulic turbine, aviation, mining machinery, metallurgy and general machinery industry, in which the processing height of 3200mm and 3500mm models are widely used in the processing of wind turbine hub.

Specification | Unit | C5231E × H/W | CQ5235E × H/W | CQ5240E × H/W | CA5240E × H/W | CA5245E × H/W | CA5250E × H/W | CAQ5260E × H/W |

Max. turning diameter | mm | 3150 | 3500 | 4000 | 4000 | 4500 | 5000 | 6000 |

Table diameter | mm | 2830 | 2830/3150 | 3150 | 3600 | 3800 | 4200 | 4500 |

Max. height of workpiece | mm | 1600/2100/2600/3200 | 1600/2100/2600/3200 | 1600/2100/2600/3200 | 2100/2600/3200/3500 | 2100/2600/3200/3500 | 2100/2600/3200/3500 | 2100/2600/3200/3500 |

Max. weight of workpiece | t | 10/16/25 | 10/16/25 | 10/16/25 | 25/32 | 25/32 | 25/32 | 25/40 |

Max. Cutting force of right Tool head | kn | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

Max. Cutting force of left Tool head | kn | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

Total cutting force |

| 63 | 63 | 63 | 63 | 63 | 63 | 63 |

Max torque of table | kn. m | 63 | 64 | 65 | 100 | 100 | 100 | 100 |

Speed steps of table |

| 16 | 14 | 14 | 16 | 16 | 16 | 16 |

Speed range of table | r/min | 2-63 | 2-40 | 2-40 | 1.25-40 | 1.25-40 | 1.25-40 | 1-32 |

Swivel angel of vertical tool head | degree | ± 30 | ± 30 | ± 30 | ± 30 | ± 30 | ± 30 | ± 30 |

Feed steps of tool head |

| 18 | 18 | 18 | 18 | 18 | 18 | 18 |

Feed range of tool head | Mm/min | 0.25-90 | 0.25-90 | 0.25-90 | 0.25-90 | 0.25-90 | 0.25-90 | 0.25-90 |

Travel of cross beam | mm | 1250/1750/2250/2850 | 1250/1750/2250/2850 | 1250/1750/2250/2850 | 1750/2250/2850/3150 | 1750/2250/2850/3150 | 1750/2250/2850/3150 | 1750/2250/2850/3150 |

Movement speed of cross beam | Mm/min | 350 | 350 | 350 | 300 | 300 | 300 | 300 |

Max. horizontal travel of right tool head | mm | 1725 | 1900 | 2200 | 1000/1250/1400 | 1000/1250/1400 | 1000/1250/1400 | 1000/1250/1400 |

Max. vertical travel of right tool head | mm | 1000/1250 | 1000/1250 | 1000/1250 | 2200 | 2450 | 2700 | 3200 |

Max. horizontal travel of left tool head | mm | 1725 | 1900 | 2200 | 1000/1250/1400 | 1000/1250/1400 | 1000/1250/1400 | 1000/1250/1400 |

Max. vertical travel of left tool head | mm | 1000/1250 | 1000/1250 | 1000/1250 | 2200 | 2450 | 2450 | 2450 |

Rapid traverse speed of tool head | Mm/min | 1560 | 1560 | 1560 | 1560 | 1560 | 1560 | 1560 |

Tool shank section (W*H) | mm | 40× 50 | 40× 50 | 40× 50 | 40× 50 | 40× 50 | 40× 50 | 40× 50 |

Power of principal motor | kw | 55 | 55 | 55 | 55 | 55 | 55 | 55 |

Machine dimension (L*W*H) | cm | 570× 440× 435 | 610× 440× 435 | 678× 440× 435 | 678× 540× 490 | 728× 540× 490 | 778× 540× 490 | 880× 540× 490 |

Net weight | t | 42 | 45 | 48 | 58 | 62 | 70 | 80 |

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com