PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

Compact Vertical Wheel Repair Machine AWR902VP

The compact vertical wheel repair machine AWR902VP is a revolution in wheel repair technology, offering unmatched stability and durability with its cast iron construction and high precision rail protection. Four-station motorized tool clamping, one-touch probe and tool switching, automatic lubrication system, and user-friendly human-machine interface design ensure high operational efficiency and precision.

- Max. rotary diameter :860mm

- Hub repair size range:: 5-34"

- Max. hub thickness: 550mm

Specifications

Specifications | Unit | AWR902VP |

Operation Control System |

| 17-inch multi-touch industrial PC system |

Optimization software |

| CNC Wheel Curve Software V2.0 |

Max. rotary diameter | mm | 860 |

Hub repair size range |

| 5-34″ |

Max. hub thickness | mm | 550 |

Chuck size |

| 13″ |

Number of chuck jaws |

| 3-jaw/Extended 3-step soft jaws (6-jaw optional) |

X/Z axis accuracy | mm | 0.001 |

X-axis travel | mm | 455 |

Distance from tool holder to chuck face | mm | 630 |

Spindle speed | rpm | 50-1500 |

Power | kw | 4 |

Tool holder control form |

| Four-station electric tool holder |

Toolholder size | mm | 25*25 |

Wheel detection method |

| Ruby probe (optional laser probe) |

Power source |

| 380v, 3 phases, or according to customer requirements |

Color |

| customizable |

Machine Size | mm | 1630*1110*1860 |

Net Weight | KG | 1530 |

Details

AWR902VP Wheel Repair Machine, with rugged cast iron construction, realizes high automation and precise control. Equipped with comprehensive rail protection, automated lubrication, user-friendly operation interface and safe electromagnetic door lock design. Equipped with advanced wheel detection and optimization software, it simplifies the operation process and improves the repair quality, making it an ideal choice for enhancing the efficiency of the repair workstation.

Gantry structure

Cast iron bed (including X-axis beam) the design structure and materials used to ensure the stability and rigidity of the overall structure of the body, so that the wheel will not appear in the cutting and repairing of vibration pattern.

High degree of automation

Four-station electric tool holder, the probe and cutting tool can realize one-key switching; the key parts of the transmission mechanism adopts automatic lubrication pump, according to the independent setting of the oiling time and frequency for automatic lubrication of the lack of oil automatic alarm.

Guide rail protection

X/Z axis linear guide rail and ball screw adopt armor plate type full protection, so that the aluminum chips generated in the process of wheel repair will not enter into the precision transmission mechanism, reducing the maintenance cycle of the equipment and greatly extending the service life of the equipment.

Man-machine friendly

The control system can be operated in two ways at the same time using the touch screen wireless keyboard and mouse; the keyboard tray adopts a 3-joint design, the operator can adjust the height of the keyboard according to their own height, free adjustment of the height of the keyboard lifting and lowering, angle of the angle of the tilt as well as the left and right rotation.

Electromagnetic door lock/hand-held unit

Electromagnetic door lock, safety door design, safe and convenient; equipment table design with circular chip chute, easy to collect and clean up aluminum chips, easy maintenance; magnetic hand-held unit, can be placed anywhere, that is, take and use.

Control system

Equipped with self-developed digital control wheel repair special software, the control system integrates all the functions of wheel profile detection, curve optimization, wheel repair cutting, etc., and adopts a touch-screen industrial computer, which is easy to operate, easy to learn and easy to use.

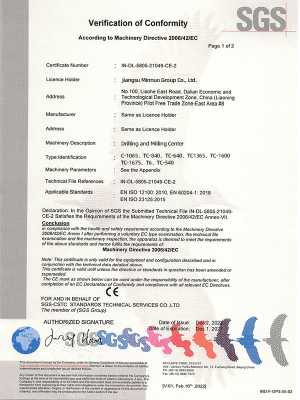

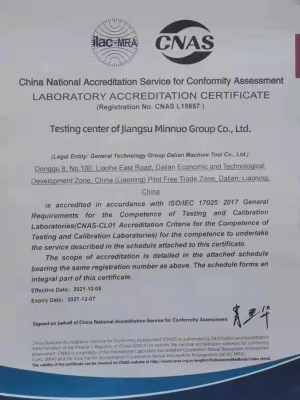

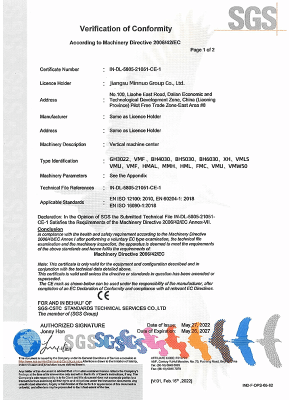

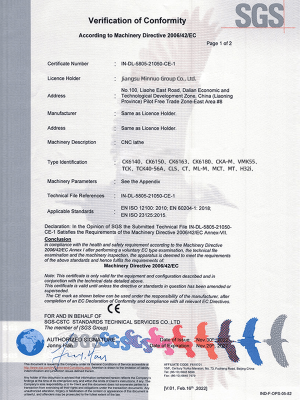

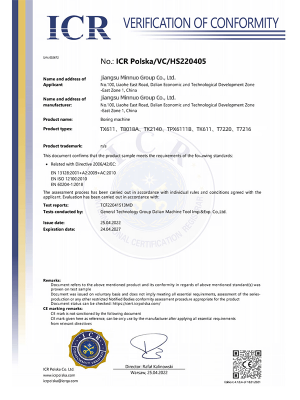

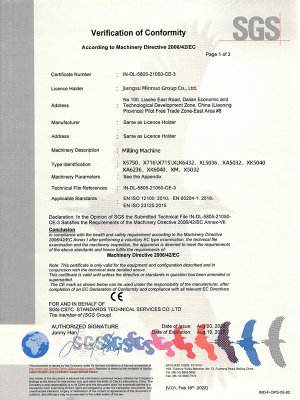

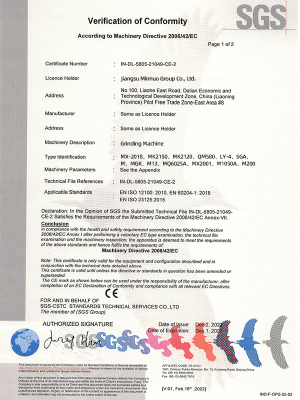

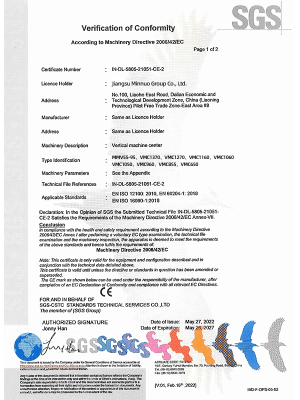

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com