PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

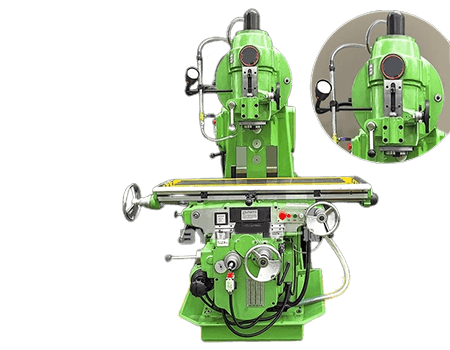

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

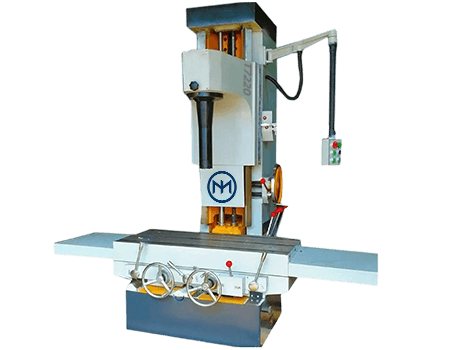

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

Vertical Wheel Repair Lathe DCM32C-S

Vertical wheel repair lathe DCM32C-S is a highly automated wheel repair lathe with one-touch motorized tool clamping and probe switching functions, as well as a four-jaw chuck with multi-jaw support, providing stable cutting and automatic shaping for wheels. Equipped with a ruby probe with an accuracy of 0.001mm, it works with the new CNC system and self-developed digital control software to realize precise repairs. Built-in monitoring, air gun and bottom roller device for convenient operation and easy maintenance.

- Max. machining size: 30”

- Max. Machining Depth: 400mm

- Power Supply Requirements: Syntec 6TA-E

Specifications

Specifications | DCM32C-S | |

Basic parameters | Max. machining size | 30” |

Max. Machining Depth | 400mm | |

Machine dimensions | 1.45*1.02*1.96m | |

Net weight: 1.5 lbs. | 1250KG | |

Power Supply Requirements | 3 phases,380V,50/60Hz | |

Control system | Syntec 6TA-E | |

Curve Optimization Software V2.0 | ||

Tool holders, probing systems, chucks | Electric four-station tool holder | |

Pneumatic chip removal cooling | ||

Ruby detection system | ||

4-jaw 250mm enlarged chuck | ||

Extended Functions | Monitor + 9-inch display | |

Exhaust air gun | ||

4 horizontal adjustable support casters | ||

Specificities

The DCM32C-S wheel lathe, features include motorized 4-station tool clamping, one-touch switching, automatic shaping of 4-jaw chucks, high-precision ruby probe, built-in monitoring and air gun, bottom wheels for easy mobility and 2-axis rail aluminum chip guards to ensure safe operation and improve maintenance efficiency.

Higher level protection: 2-axis track aluminum chip guard, blocking aluminum chips from entering and guarding the safe operation of the machine.

Control system: new CNC wheel repair system, strong and stable operation; provide self-developed digital control wheel repair special software.

High degree of automation: 4-station motorized tool holder with one-touch switching for probe and cutting tool; 3 different tools and 1 probe can be installed.

Four-jaw chuck: multi-jaw support, more stable cutting; can make the slightly deformed wheel automatically rounded.

Probing system: ruby probe with 0.001mm precision, suitable for detecting different shapes of wheel curves.

Monitor / Foma wheel / air gun: camera monitoring function, multi-angle monitoring of the operation status; built-in air gun, within reach, easy to remove aluminum chips on the wheel and in the operating room; bottom foma wheel device, convenient to move the machine at any time, no need to call a forklift.

Wheel Repair Show

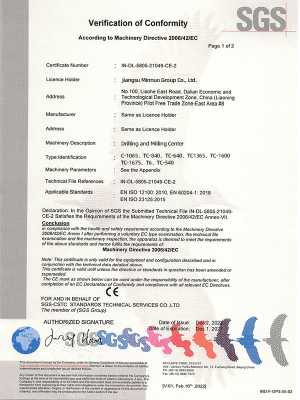

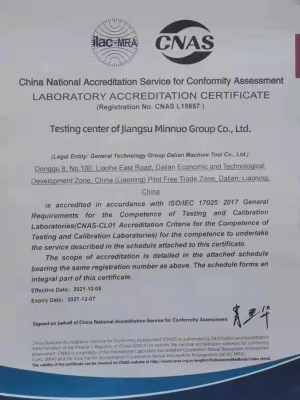

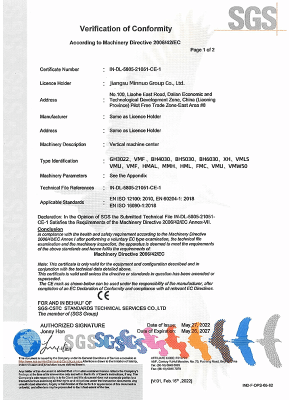

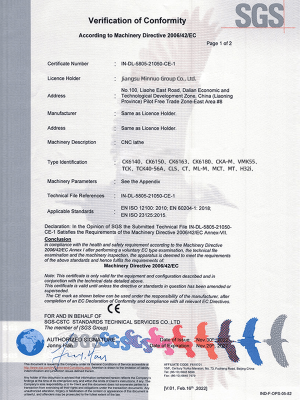

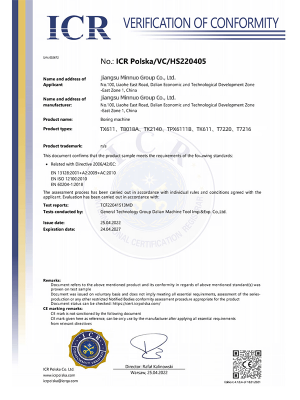

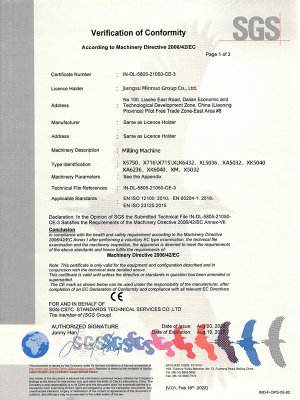

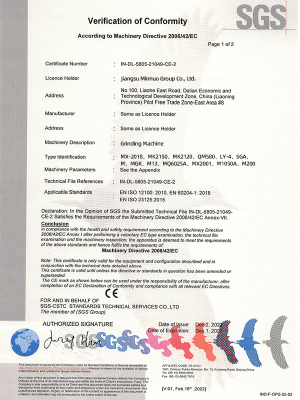

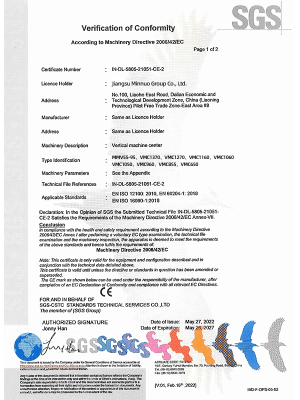

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com