PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

CNC Wire EDM DK77 Series

CNC wire EDM DK77 series, known for its high rigidity, high precision and imported key components, adopts advanced technology and materials to provide high automation and user-friendly operation interface for precision machining of a wide range of materials.

- Worktable size: 270*420mm

- Worktable travel:200*250mm

- Max. workpiece height: 200mm

Products

Mechanical part

High-speed graphite EDM machine host high rigidity, non-structural parts of the design and high-precision imported key devices used to ensure that the entire machine tool geometric accuracy, motion accuracy and machining accuracy to meet the domestic standards for similar products.

- High rigidity column structure, high-precision manufacturing standards and high-precision retention.

The main body adopts “ram” structure. The castings are made of high-quality strong cast iron, which are treated with secondary tempering and long-term aging, effectively suppressing the deformation of cast iron that may be brought about by years of use.

- Advanced quality key components of CNC a*es

The transmission system of CNC a*es all adopt imported high-precision screws, guide rails and bearings, and connect with Panasonic motors to ensure high precision and high rigidity characteristics, and realize high-precision control of CNC a*es of machine tools.

- Use of high performance materials

The worktable adopts fine grinding cast iron worktable, good accuracy is the effective guarantee of precision machining.

- Use of perfect temperature control

The use of temperature sensors, liquid temperature controller and liquid level controller, standard configuration of fire e*tinguishers to ensure the safe operation of the user’s machine tools.

CNC power supply device part

- Configuration of key components

- Adopting advanced industrial computer motherboard control; 15″ high-resolution TFT-LCD display;

- The drive system adopts Panasonic all-digital AC servo system with a minimum resolution of 0.1μm;

- The numerical control system adopts the current international advanced large-scale highly integrated FPGA chip.

- Technical performance of the brief description

- The power supply adopts the current advanced discharge control and CNC control technology; configured with ultra-fine machining circuit and servo system with high-speed response and stable machining.

- The power supply has a variety of shaking methods;

- The discharge control part digests and absorbs * technology and uses newest upgraded circuit technology.

- Discharge processing technology database software

- The system is equipped with a rich process software database, a variety of electrodes and workpiece combination, can be a variety of materials for automatic processing and manual processing

- Especially for the processing of some special materials, this machine tool provides users with a wide range of options

- Such as processing cemented carbide materials, high-temperature alloys, titanium alloys, power supply has a very strong target, processing the surface of the metamorphosis of the layer is small, the impact of the surface hardness (HRC) small surface hardness (HRC) influence and other advantages.

Product Parameter

Type | Worktable size(mm) | Worktable travel(mm) | Max. workpiece height(mm) | Taper(optional) | Max. workpiece weight(kg) | Machine weight(kg) | Machine dimension(L*H) | Power consumption |

DK7720 | 270*420 | 200*250 | 200 | 60/80mm | 100 | 800 | 1160*880*1400 | AC380V/220V 50Hz

|

DK7725 | 340*520 | 250*220 | 400 | 60~120/80 | 200 | 1200 | 1485*1010*1700 | |

DK7730 | 340*560 | 300*360 | 400 | 60~120/80mm | 200 | 1250 | 1485*1050*1700 | |

DK7732 | 380*600 | 320*400 | 400 | 60~300/80mm | 300 | 1400 | 1640*1280*1700 | |

DK7735 | 380*650 | 350*450 | 400 | 60~300/80mm | 300 | 1440 | 1660*1330*1700 | |

DK7740 | 410*710 | 400*500 | 400 | 60~600/80mm | 450 | 1600 | 1830*1490*1700 | |

DK7740B | 450*840 | 400*630 | 400 | 60~600/80mm | 450 | 1670 | 1845*1610*1700 | |

DK7745 | 500*750 | 450*550 | 400 | 60~600/80mm | 450 | 1650 | 1865*1520*1700 | |

DK7755 | 596*880 | 550*650 | 500 | 60~600/80mm | 800 | 2500 | 2070*1170*1790 | |

DK7755B | 596*1060 | 550*850 | 500 | 60~600/80mm | 850 | 2600 | 2070*1950*1790 | |

DK7763 | 790*1260 | 6300*1000 | 600 | 60~600/80mm | 1000 | 3500 | 2265*2160*1930 | |

DK7763A | 720*1260 | 630*1000 | 600 | 60~600/80mm | 1000 | 3200 | 2200*2160*1930 | |

DK7780 | 900*1500 | 800*1200 | 600 | 60~600/80mm | 1500 | 5500 | 2900*2500*2150 | |

DK7780A | 880*1440 | 800*1200 | 600 | 60~600/80mm | 1500 | 4700 | 2700*2300*1900 | |

DK7780B | 880*1260 | 800*1000 | 600 | 60~600/80mm | 1500 | 4500 | 2620*2260*1900 | |

DK77100 | 1010*1500 | 1000*1200 | 600 | 60~120/80mm | 1500 | 5600 | 2930*2500*2000 | |

DK77120 | 1300*1900 | 1200*1600 | 500 | 60~120/80mm | 4000 | 10000 |

|

Function

Machine Performance

- Adaptive discharge machining control.

- Timed high-speed knife lifting and knife lifting height control.

- Spindle fi*ed point control and discharge gap detection.

- Oil level control.

- Fire prevention control.

- Anti-accumulation carbon function.

- CNC system, hand control bo*

- Mirror surface processing.

- *, Y, Z a*is Panasonic servo system.

- Minimum electrode loss 0.1%.

- Optimum surface roughness Ra0.2um.

- Highest productivity 300mm³/min.

- Minimum driving unit 1um.

CNC Power Supply Unit Performance

- 15 inch LCD liquid crystal display.

- Mirror processing and carbide special processing circuit.

- AUTO machining function unit.

- Automatic positioning function unit.

- High speed and high precision machining system.

- Automatic arc clearing circuit unit.

- Simple and intuitive form-filling type work code processing.

- Power failure reset, error message prompting function.

Related Products

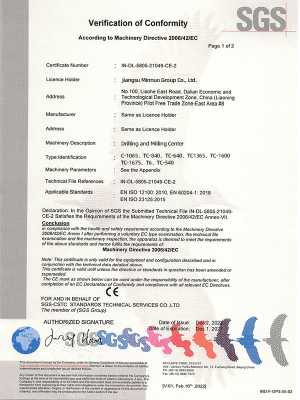

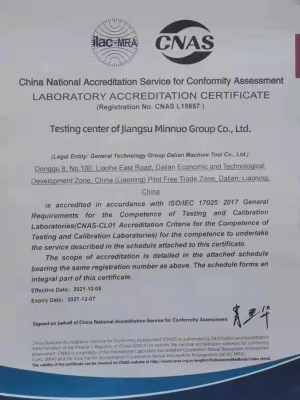

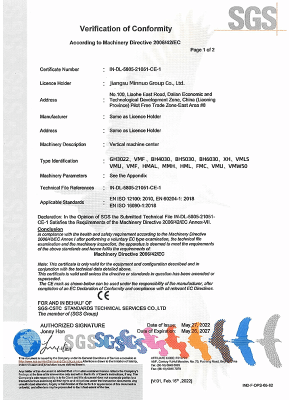

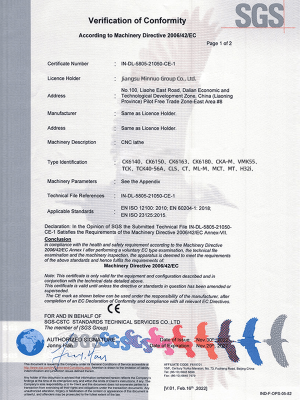

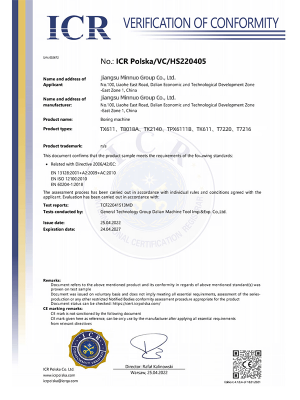

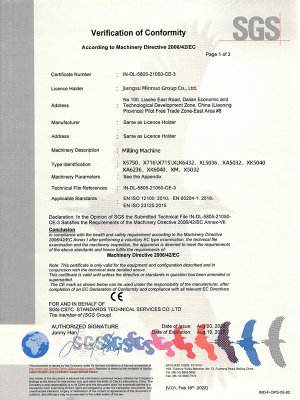

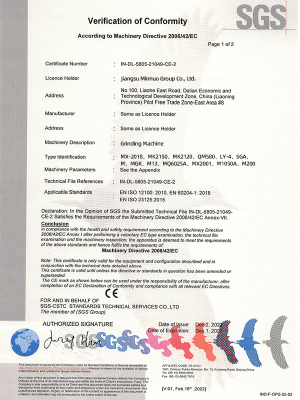

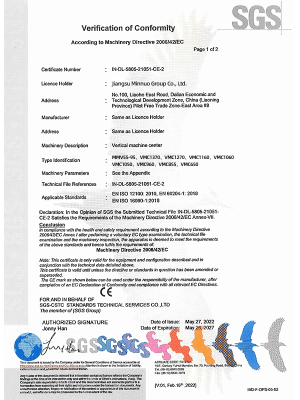

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com