PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

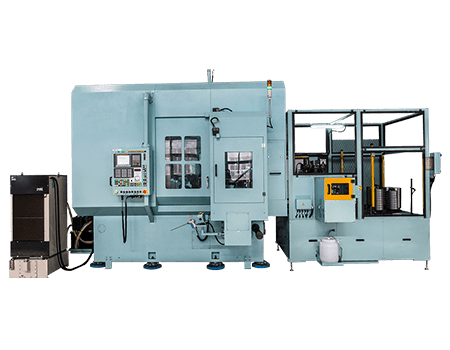

YD3132 CNC Dry Gear Hobbing Machine

YD3132CNC dry gear hobbing machine is a 10-axis CNC hobbing machine, with dual channels and two working stations for simultaneous operation, featuring a combination of linear and rotary CNC axis for precision gear manufacturing.

- Max. workpiece diameter: φ220mm

- Max. diameter of installed hobbing cutter:φ100mm

- Max. length of installed hobbing cutter:200mm

Specifications | Unit | YD3132CNC |

Max. workpiece diameter | mm | φ220 |

Max. modulus | mm | 4 |

Helical angle of machined helical gear (A-axis) | ° | 士45 |

Max. diameter of installed hobbing cutter | mm | φ100 |

Max. length of installed hobbing cutter | mm | 200 |

Max. axial movement of hobbing cutter (Y-axis) | mm | 200 |

Horizontal distance from center of hobbing cutter to center of worktable(X-axis) | mm | 35~175 |

Vertical distance from center of hobbing cutter to surface of worktable (X-axis) | mm | 80~430 |

Distance from hobbing tailstock to hobbing workbench face | mm | 300~650 |

Speed range of hobbing cutter spindle (B-axis) | rpm | 1~2700 |

Speed range of worktable (C-axis) | rpm | 1~250 |

Radial quick movement speed (X-axis) | mm/min | 10000 |

Tangential moving speed (Y-axis) | mm/min | 5000 |

Axial quick movement speed (Z-axis) | mm/min | 7000 |

CNC system | SIEMENS SINUMERIK 828D | |

Motor total power | KW | 51.28 |

Rated output power of main motor | KW | 22 |

Occupation area of machine | mm | 2950*3860*2670 |

Net weight of machine | Kg | 9000 |

Features

The CNC gear hobbing machine offers high-precision, rigidity, and flexibility with independent servo motor control for all axes, zero-backlash transmission, variable speed B-axis for high-efficiency hobbing, and options for automatic tooth correction and scraping.

- The machine features a chamfering station and a four-position exchange manipulator, enabling the gear hobbing and chamfering process.

- Each axis is directly controlled by an independent AC servo motor, which provides characteristics such as a short transmission chain, good transmission rigidity, and high transmission precision. Both the rotary axis of the worktable (C-axis) and the rotary axis of the hobbing spindle (B-axis) are driven directly by built-in spindle motors, achieving zero-backlash transmission and significantly enhancing spindle drive rigidity and dynamic response speed.

- The hobbing spindle (B-axis) allows stepless speed regulation within a range of 1-2000 RPM, making it particularly suitable for high-speed, efficient dry gear hobbing with multi-head hobs.

- The main guide rail pairs use high-precision, high-rigidity roller linear guides, providing good transmission rigidity, high load-bearing capacity, and high linear motion accuracy.

- The machine can be equipped with an automatic tooth alignment device for hard gear surface shaving operations.

Applications

- CNC dry gear hobbing machine is widely used in automotive, aerospace, machinery manufacturing and other industries, is one of the indispensable equipment for modern gear processing.

CNC gear hobbing machine works by hobbing wheel driven hob, compared with the traditional milling machine and grinding machine, CNC gear hobbing machine can efficiently carry out high-precision hobbing processing.

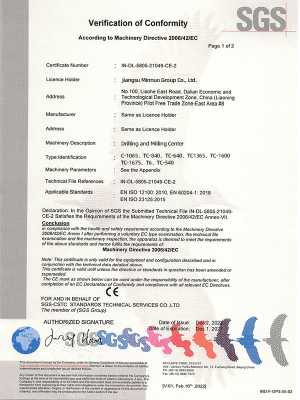

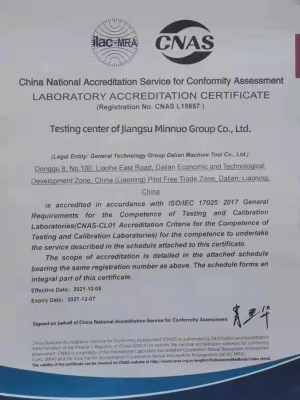

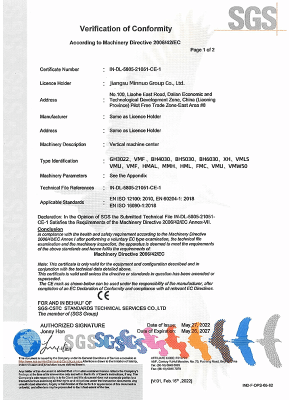

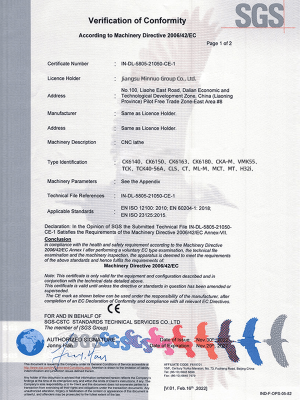

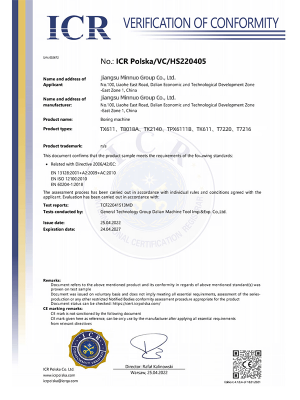

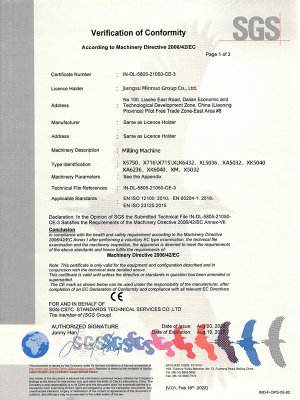

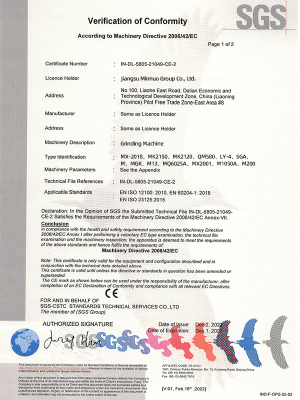

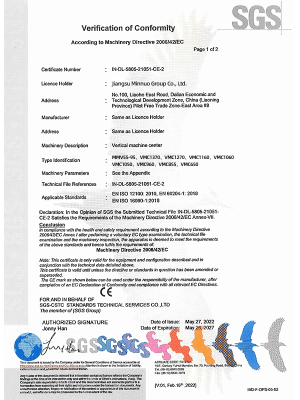

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com