PRODUCTS CATEGORY

Intelligent Manufacturing Production Line

+Machining centers

+Lathe Machine

+Milling Machine

+Grinding Machine

+Drilling Machine

+Metal forming equipment

+Boring machine

+Machine Tool Accessories

+Specialized Machines

+Electrical Discharge Machine

+Related News

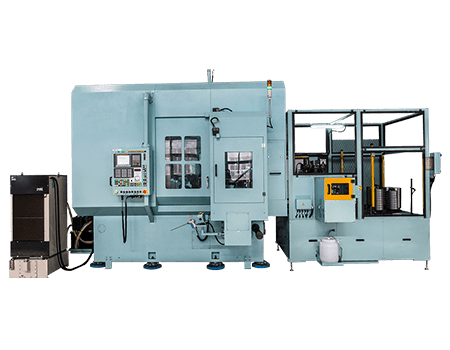

YW4240 CNC Universal Gear Shaving Machine

Gear shaving machine to gear-shaped shaving cutter as a tool to finish the gear tooth surface has been processed, this processing method is called “shaving”. The Universal Gear Shaving Machine is a machine tool for machining complex mechanical parts such as gears, worm gears, cams, guide rails, etc. It works on the principle of shaving. Its working principle is based on the principle of shaving processing, through the high-speed rotation of the razor to scrape off the material on the surface of the workpiece, so as to form the required shape and size.

- Max. outside diameter of workpiece: 400mm

- Max. outside diameter of tool:250mm

- Max. distance between centers:500mm

Specifications | Unit | YW4240CNC |

Gear shaving method |

| Ax1a1, rad1a1, |

Workpiece: Max. outside diameter | mm | 400 |

Max. modulus | mm | 8/5 ( Rad1a1 gear |

Max. tooth width | mm | 130 |

Tool: Max. outside diameter | mm | 250 |

Max. cutter width | mm | 50 |

Mounting bore diameter | mm | 63.5 |

Max. distance between centers | mm | 500 |

Center distance between workpiece and gear shaving machine | mm | 125~335 |

X- axis axial feeding: Max. stroke | mm | 150 |

Speed: High speed | mm/ min | 500 |

Working feed | mm/ min | 10~150 |

Min. increment | mm | 0.001 |

Y- axis radial feeding: Max. stroke | mm | 40(±20) |

Speed: High speed | mm/ min | 500 |

Working feed | mm/ min | 10~150 |

Min. increment | mm | 0.001 |

Z- axis axial feeding: Max. stroke | mm | 210 |

Speed: High speed | mm/ min | 480 |

Feed | mm/ min | 0.2~4 |

Min. increment | mm | 0.001 |

A- axis rotation range |

| ±20° |

Max. speed | rpm | 1.82 |

Min. increment |

| 0.001° |

Spindle speed: | rpm | 50~400( Step1ess) |

Main motor( Spindle motor) | KW | 7.5 |

X- axis servo motor | Nm | 8 |

Y- axis servo motor | Nm | 8 |

Z- axis servo motor | Nm | 8 |

A- axis servo motor | Nm | 12 |

Hydraulic motor | KW | 1.1 |

Total power of machine | KW | 16.1 |

Dimensions | mm | 2450×2500×2700 |

Weight | kg | 6000 |

Features

The YW4240CNC CNC gear shaving machine is a fully functional CNC gear shaving machine developed by our company. The machine adopts a new processing principle and advanced control technology, offering excellent rigidity and high machining accuracy with convenient operation and adjustment. The machine features 5-axis CNC (FANUC 0I F control system), with the five axes being: tool spindle rotation (C axis), tool radial feed (Z axis), tool tangential feed (Y axis), worktable axial feed (X axis), and tool holder rotation (A axis).

- The CNC gear shaving machine abandons the mechanical structure of worktable lateral swing for shaving crowned teeth and small taper teeth. Instead, when shaving crowned and small taper teeth, the linear coordinate axes drive the tool and workpiece to move along preset spatial curves, forming the ideal tooth profile curve. This eliminates the inherent weaknesses of traditional gear shaving machines that affect machine rigidity and machining accuracy.

- The machine uses proprietary control software developed by our company, featuring a clear and intuitive interface with convenient and fast programming. By directly inputting the corresponding tool, workpiece, and processing parameters, the machine automatically generates the machining program, achieving true parametric programming for the CNC gear shaving machine. Used programs can be saved for future use.

- The machine offers four shaving methods: axial, radial, tangential, and diagonal, capable of shaving crowned teeth and small taper teeth. With specialized software, it can also shave special tooth profile curves.

- The X, Y, and Z axes movements are driven by servo motors through the shortest mechanical transmission to imported high-precision, high-rigidity ball screws. The guide rails for the X, Y, and Z axes use imported high-precision, high-rigidity roller linear guides.

- For convenient tool changes, the machine uses imported liquid plastic nuts to lock the tools.

Applications

- YW4240 CNC universal gear shaving machine universal gear shaving machine is a powerful, efficient and flexible machine tool for processing various types of gears, worm gears, cams, guide rails and other complex mechanical parts.

Universal gear shaving machines are based on the principle of shaving processing. During the machining process, the shaving cutter rotates at high speed while feeding the workpiece according to a specific trajectory, thus shaving off the material on the surface of the workpiece to form the desired shape and size. The relative motion of the razor and the workpiece is controlled by a drive system. During the machining process, coolant is continuously sprayed on the razor and the workpiece to reduce temperature and lubricate.

Certified Quality

We are fully committed to the highest standards of quality for our development andmanufacturing processes as well as to preserving the environment. Our products haveobtained a number of domestic and foreign authoritative certifications.

Get In touch

(+86) 13295238763

24 hours online service

Address No. 2 Xintai Road, Economic and Technological Development Zone Jingjiang City Jiangsu Province, China

Email cncitd@minnuo.com